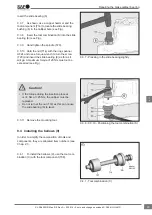

8.2.15 Using your hand, press the mandrel of the

press-in tool (M) as far as it will go. Then use a

hammer to drive it in as far as it will go (see Fig.).

Note: After fitting the new cover (68), a 15.5 mm

protrusion of the cover (68) with respect to the flat

surface must be ensured (see Fig.).

Fitting the cover with the brake calliper (1) and

carrier (2) removed:

8.2.16 Check the brake calliper for slight move-

ment (see Chap. 5.3).

8.2.17 In the clamping position shown (e.g. vice),

press the carrier (2) as far as possible against the

brake calliper (1).

The inner bellows (9) must be compressed

(see Fig.) as otherwise the movement of the

brake calliper will be restricted.

Danger !

8.2.18

The cover (10) or (68) can only be fitted as

described above (see Chap. 8.2.10 to 8.2.15).

8.2.19 Mount the carrier complete with brake cal-

liper to the axle (use only new screws, observe the

prescribed tightening torques).

Note: When mounting to the vehicle axle,

the regulations from the respective vehicle

manufacturer must be observed.

8.2.20 Install the brake pads (see Chap. 6.2).

8.2.21 Check the adjustment function (see

Chap. 5.2).

8.2.22 Fit the diaphragm or combined chamber

(see Chap. 11.2 or 11.4). Then adjust the clear-

ance. See Chap. 5.2.6.7.

8.2.23 Fit the wheels (observe the information

from the axle/vehicle manufacturer)

After completing work on the disc brake, always

perform a final check on the roller test bench to

verify function and effectiveness. Note that the

brake pads and/or brake disc may have reduced

braking efficiency during their run-in phase.

Danger !

8.2.15 - Driving the press-in tool (M) with a hammer

as far as it will go

8.2.17 - Pressing the carrier (2) against the brake

calliper (1)

Removing and installing the brake calliper

39

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND