Threaded holes must be free of lubricants,

grease and residues of screw locking agent!

Caution!

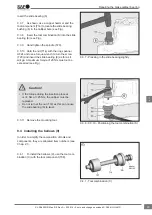

8.2.4 Position the brake calliper (1) on the carrier

(2) and tighten the socket cap screws (39) and (40)

to 180 Nm and 90° angular post-tightening (use

only new parts) (see Fig.).

8.2.5 Check the brake calliper for slight move-

ment (see Chap. 5.3).

8.2.6 Install the brake pads (12) (see Fig. and

Chap. 6.2). Now fit the cover. See Chap. 8.2.10.

8.2.7 Check the adjustment function (see

Chap. 5.2).

8.2.8 If present, remove tape from the replacement

brake calliper - see arrow Y. If re-using the old

brake calliper, all components of the calliper guides

and socket cap screws must be replaced with a

suitable guide and seal kit.

8.2.9 Fit the diaphragm or combined chamber (18)

(see Fig. and Chap. 11.2 or 11.4).

Fit the cover variants

The cover may only be fitted once the brake

calliper has been fully bolted to the carrier (see

Chap. 8.2).

Caution!

Cover variant (10), long bearing side

The seating surface of the cover (10) in the calliper

bore must be free of grease!

8.2.10 Clean the new cover (10) thoroughly. Clean

the inside area of the press-in tool (H) and place

the cover inside (see Fig.).

8.2.11

Ensure that the flat surface and chamfer

of the calliper bore are not damaged - see arrow.

Position the press-in tool (H) with cover (10) on the

flat surface of the calliper bore (see Fig.).

Note: Do not tilt the tool!

8.2.5 - 8.2.9 - Placing the brake calliper on the

carrier, tightening the socket cap screws, installing

the brake pads, removing the combined or

diaphragm chamber

8.2.10 - Placing the cover in the press-in tool (H)

8.2.11 - Positioning the press-in tool (H) with cover

on the flat surface of the calliper bore

Removing and installing the brake calliper

37

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND