5.2 Inspecting the adjustment function

5.2.1 Always secure the vehicle to prevent it from

rolling away before commencing repair and service

work.

5.2.2 The service/parking brake and, on buses,

the frequent-stop brake, must be released.

5.2.3 Check the supply pressure of the brake

system (target: >6.5 bar), connect an external sup-

ply to prevent loss of pressure.

5.2.4 Jack up the vehicle or axle and remove the

wheel (observe the information from the respective

axle/vehicle manufacturer).

5.2.5 Check the temperature of the brake disc. It

must be between -10°C and 50°C.

5.2.6 Check the clearance as follows:

5.2.6.1 Move the brake calliper backwards and

forwards in the guide to check that there is clear-

ance. If necessary, clean the brake and/or repair

the bearings (see Fig.) (see Chap. 9).

5.2.6.2 Actuate the brake once with medium

pressure (approx. 2-3 bar). If the brake cannot be

actuated, slide the brake calliper on its guide pin in

the direction of the centre of the vehicle (see Fig.).

5.2.6.3 Using a suitable tool, press the inner brake

pad (12) away from the pressure fittings (13)

(see Fig.).

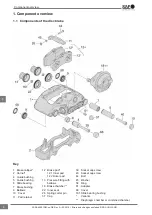

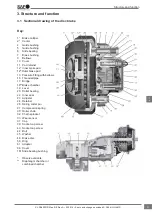

5.2.6.1 - Sliding the brake calliper backwards and

forwards in the guide three times

5.2.6.2 - Sliding the brake calliper on its guide pin in

the direction of the inner pad

5.2.6.3 - Pressing away the inner brake pad

5.2.6.4 - Removing the cap and using the adapter

on the adjuster

Ensure that there is no dirt between the outer pad

backs and calliper contact surface as this could

produce inaccurate results. Clean if necessary.

Caution!

5.2.6.4 Remove the cap (37) with the tab (do not

lose the adapter (61) (see Fig.).

Removing the cap (37) with auxiliary equipment can

damage the adjuster seal.

5.2.6.5 Set the initial clearance to 1.3 mm by un-

screwing and then screwing in the brake with the

adapter (61). Set the clearance on the side of the

brake that is turned.

5.2.6.6 Actuate the brake 20x with medium pres-

sure (approx. 2-3 bar).

Function and visual inspection

16

en

XL-SA40001RM-en-DE Rev A • 02.2016 • Errors and changes excluded © SAF-HOLLAND