15

GENERAL

230V power L

X1

-01-

1

230V power

N

X1

-01-

2

PE

X1

-01-

3

L

au

x

X1

-02-

1

N

au

x

X1

-02-

2

Fan power L

X2

-01-

1

Fan power

N

X2

-01-

2

L pi

1

X2

-02-

1

N

pi

1

X2

-02-

2

Lockout L

X2

-03-

1

N

X2

-03-

2

L-

Vm

ix

X2

-04-

1

Commo

n

X2

-04-

2

L-

PB

X2

-04-

3

ER

X2

-05-

1

Si

c

X3

-01-

1

Si

c

X3

-01-

2

VG

230V

RC

X3

-02-

1

VG

230V

RC

X3

-02-

2

N

T-

at

X3

-03-

1

L T-

at

X3

-03-

2

0

M

X3

-04-

1

GND

Fan cont

ro

l

X1

4-

1

+U

B

Fan cont

ro

l

X1

4-

2

HA

LL F

an cont

ro

l

X1

4-

3

PW

M

Fan cont

ro

l

X1

4-

4

+ 26

V

X1

1-

1

Si

c1

X1

1-

2

Si

c2

X1

1-

3

X1

1-

4

X1

1-

5

VD

C

X1

1-

6

IN

X1

1-

7

AN

4 Sf

um

i

X1

1-

8

AN

3

BW

1

X1

1-

9

AN

2 SR

X1

1-

10

AN

1 SM

X1

1-

11

+5

V

X1

1-

12

AN

5 +5

V

SE

X1

0-

06-

2

AN

5

-I-S

E

X1

0-

06-

1

AN

3 +5

V

SB

X1

0-

05-

2

AN

3

I SB

X1

0-

05-

1

X1

0-

04-

2

X1

0-

04-

1

Si

c-

X1

0-

03-

2

Si

c-

X1

0-

03-

1

TA

1

X1

0-

02-

2

TA

1

X1

0-

02-

1

TA

2-

S

QAA

73

X1

0-

01-

2

TA

2-

GND

QAA7

3

X1

0-

01-

1

AGU2.5

X50-5

AGU2.3

X30-14

OCI420

X40-5

X30-1/14

T1

T2

T3

T4

T5

T6

T7

T8

T9

T10

L1 N PE

1

2

AT

PE

Fan-PWM

L1 N PE

RIV

L1

1

L

2

N1

3

N

4

PE

5

FILTRO

6.3A

C1

-L

3

C1

-N

C1

-P

E

C1

-L

1

C1

-L

2

M9 M8

M7 M6 M5 M4

M20

M21

M10

M11

M

+

1

TA

C

2

PE

3

DCV

PV

M

4

-

5

L1

N

PE

M1 M2 M3

FI

FU

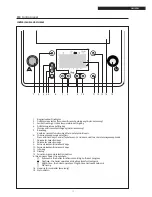

Electrical connections

to be made by the

heating engineer

IG

PI

PB

Sb

TF

Pcaldaia

Sm

SE

SCH2

SCH1

(*)

VE1

H2

TS

Treg

A

B

C

D

E

F

G

TR1

ER

EA

Sr

Sf

L1

L2

PE

N

L3

L1

L2

PE

N

L3

PE

N

L3

TA

230 Vac

VG1

230V~50Hz

C

A

B

D

E

F

G

open

Y1

clos

e

Y2

BSB

-4

p

BS

B

NA

/0-10V

H1

Pi

mp

ianto1

Q2

QX

1

QX

1

St.cyl. pump

Q3

1st stage

L1

PE

PE

T1

T1

N

N

T2

T2

X30-10

p

X3

0

L1

L1

S3

S3

N

N

CH1 snsr

BX

1

BX

1

ground

M

Boiler snsr

B2

DHW 1 snsr

B3

Out. temp. snsr

B9

ground

BX

2

BX

2

LPB-

4p

LP

B

ground

M

X5

0-5p

X5

0

X6

0-6p

X6

0

LPB

DB

ground

MB

L

L

PE

PE

S3

S3

4

4

SK

2

SK

2

SK

1

SK

1

N

N

N

N

N

N

N

N

PE

PE

PE

PE

PE

PE

PE

PE

M

M

M

M

M

M

M

M

CL

+

CL

+

CL

+

CL

+

CL

-

CL

-

CL

-

CL

-

G+

G+

SCH3

SCH4

DB-LPB

MB-LPB

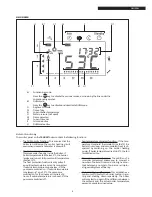

LMU

Clip-in

communication card

L

230

V

N

230V

L

P1

N P1 C

va

l

C

co

mu

n.

A

va

l

NTC/10K

NTC 10K

SCH5

PI1

VM1

SI1

B1 M

Pa Pa

Fan - PWM

TA

Room thermostat (low voltage, 24V)

FU

Fuse 6.3 A-T

IG

Main switch

FI

Mains filter

Treg

Connection for temperature controller (accessory)

TF

Flue gas thermostat, 75°C (+0/-10)

Pboiler Pressure switch (combustion chamber)

SCH1

Main board

SCH2

Display and control card

ER

Flame detection electrode

EA

Ignition electrode

TS

Safety thermostat, 100°C (+0/-6)

TR1

Ignition transformer

VG1

Gas valve

H2

Burner lockout indicator

VE1

Variable speed fan

PI

CH pump

PB

Storage cylinder pump (accessory)

SE

Outdoor sensor (supplied)

Sm

CH flow temperature sensor

Sr

Control temperature sensor

Sb

Storage cylinder temperature sensor (accessory)

Sf

Flue gas temperature sensor

(*) 230Vac output for alarm connection

BOILER CONTROL PANEL

1 .12

Wiring diagram