45

8.5 ELECTRICAL CHECKS

Any electrical checks must be carried out by a suitably qualified

person.

8.5.1 EARTH CONTINUITY TEST

Isolate the appliance from the electrical supply, and using a

suitable multi-meter carry out a resistance test. Connect test

leads between an appliance earth point and the earth wire of

the appliance supply cable. The resistance should be less than

1 OHM. If the resistance is greater than 1 OHM check all earth

wires and connectors for continuity and integrity.

8.5.2 SHORT CIRCUIT CHECK

Isolate the appliance from the electrical supply, and using a

suitable multi-meter, carry out a short circuit test between the

Live & Neutral connections at the appliance terminal strip.

Repeat above test on the Live & Earth connections at the

appliance terminal strip.

NOTE

Should it be found that the fuse has failed but no fault is

indicated, a detailed continuity check will be required to trace

the fault. A visual inspection of components may also assist in

locating the fault.

8.5.3 POLARITY CHECK

With the appliance connected to the electrical supply and using

a suitable multimeter, carry out the following voltage tests:

• connect test leads between the Live & Neutral connections

at the appliance terminal strip. The meter should read

approximately 230V ac. If so proceed to next stage. If not,

see section 8.6.

• connect test leads between the Live & Earth connections at the

appliance terminal strip. The meter should read approximately

230V ac. If so proceed to next stage. If not, see section 8.6.

• connect test leads between the Neutral & Earth connections

at the appliance terminal strip. The meter should read

approximately 0 – 15Vac. If so polarity is correct. If not, see

section 8.6.

8.5.4 REVERSED POLARITY OR SUPPLY FAULT

Repeat the above tests at the appliance isolator, if testing

reveals correct polarity and/or supply at the isolator, re-check

wiring and connections between the isolator and the appliance.

If tests on the isolator also reveal reversed polarity or a supply

fault, consult the local electricity supplier for advice.

DISTANCE TO EARTH CHECK

Isolate the appliance from the electrical supply, and using a

suitable multi-meter carry out a resistance test. Connect test

leads between the Live & Earth connections at the appliance

terminal strip. If the meter reads other than infinity there is a

fault that must be isolated, carry out a detailed continuity check

to identify the location of the fault.

These series of checks must be carried out before attempting

any faultfinding procedures on the appliance. On completion

of any task that required the disconnection and re-connection

of any electrical wiring or component, these checks must be

repeated.

8.6 FAULT FINDING

Before attempting any faultfinding, the electrical checks as

detailed in section 8.5 must be carried out. Isolate the appliance

from the electrical supply.

Disconnect any external controls from terminal plug, and insert

a link-wire between the two wires at the ‘TA’ connections of the

8-poles connector.

NOTE:

restore the electrical supply to the boiler and RESET

functionning. The boiler should now function as described

in section 8.2. Should the boiler fail to respond, the internal

fuses and connectors should be checked to ensure integrity

and continuity.

8.7 APPLIANCE STATUS AND FAULT CODES

When the boiler detects a temporary fault condition, the

appropriate code is shown. If/when the fault is final, the pump

will perform 30 to 60-second post circulation (depending on the

error code) and fault code will be displayed. For combustion

fault, FAN can also post vent up to 5min if required.

8.8 REC10CH SYSTEM RESET

Warning! – This operation must only be carried out by

qualified personnel!

If required, the system configuration can be reset back to the

factory default configuration; however care needs to be taken

in order to carry out a successful reset:

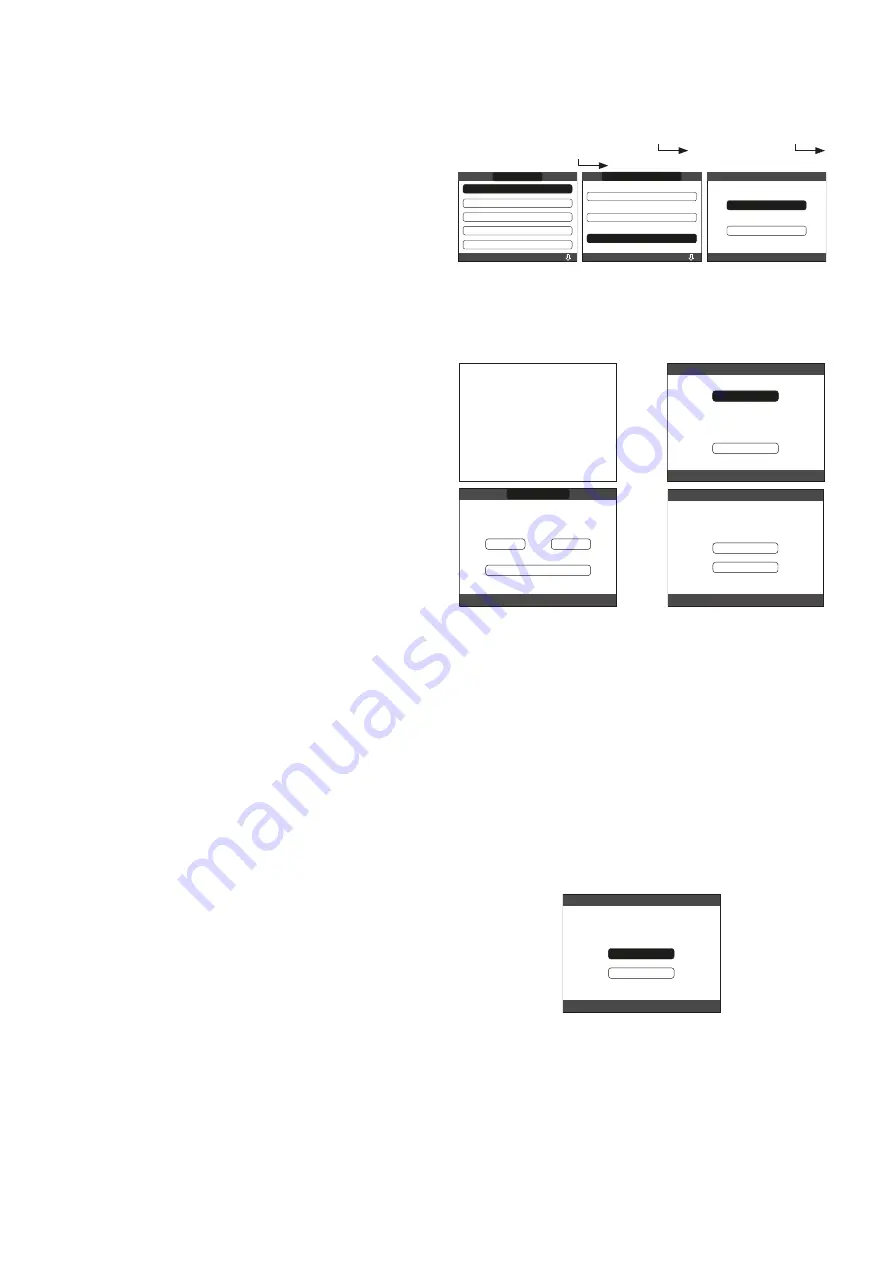

- access to menu TECHNICAL

INSTALLATION

SYSTEM RESET

CONFIRM or CANCEL

CANCEL

CONFIRM

ZONES MANAGER

SENSOR CALIBRATION

SYSTEM RESET

INSTALLER

INSTALLATION

RANGE RATED

WEATHER COMPENSATION

PARAMETERS

CALIBRATION

INSTALLATION

INSTALLER

TECHNICAL

-

the UI screen will display the firmware version – press any

key to continue

- select language (ENGLISH)

- enter the time and date

- select MASTER

-

select configuration type: NEW or

MAIN PCB (see below)

ITALIANO

ENGLISH

MULTI ZONE CONTROLLER

REC10 V01.26

PRESS ANY KEY

TO CONTINUE

SELECT THE TYPE

OF CONFIGURATION

NEW

FROM AKM

MAIN PCB

12

17

:

ENTER TIME AND DATE

TIME & DATE

USE THE ARROWS TO MODIFY

18 / 11 / 2013

8.8.1 BOILER CONFIGURATION

The BOILER menu allows you to change the hydraulic confi-

guration without necessarily having to go through a SYSTEM

RESET operation.

The HYDRAULIC CONFIG parameter can assume values

between 0 and 4 with the following meaning:

0 = System boiler (heating only boiler)

1 = Combination boiler (instantaneous) with flowswitch

2 = Combination boiler (instantaneous) with flowmeter (Flux

meter)

3 = System boiler & cylinder with probe

4 = System boiler & cylinder with thermostat.

8.8.2 CONFIGURATION FROM AKM PCB

- S

elect configuration type:

MAIN PCB

- The REC10CH will use the information/settings stored on

the AKM PCB to configure the appliance

SELECT THE TYPE

OF CONFIGURATION

NEW

MAIN PCB

8.8.3 NEW CONFIGURATION

- S

elect configuration type:

NEW

- Select location of REC10CH:

ON BOARD

- Select PLANT type:

CH ONLY

–

INSTANTANEOUS

–

HW

(STORAGE TANK)

(see below)