Printing on Thick or Thin Paper

23

1

Printing on Thick or Thin Paper

When you make prints on thick (127.9

to 209.3g/m

2

, 34.0 to 55.6 lb), stan-

dard (52.3 to 127.9g/m

2

, 13.9 to 34.0

lb) or thin (47.1 to 52.3g/m

2

, 12.5 to

13.9 lb) paper, perform the following

steps.

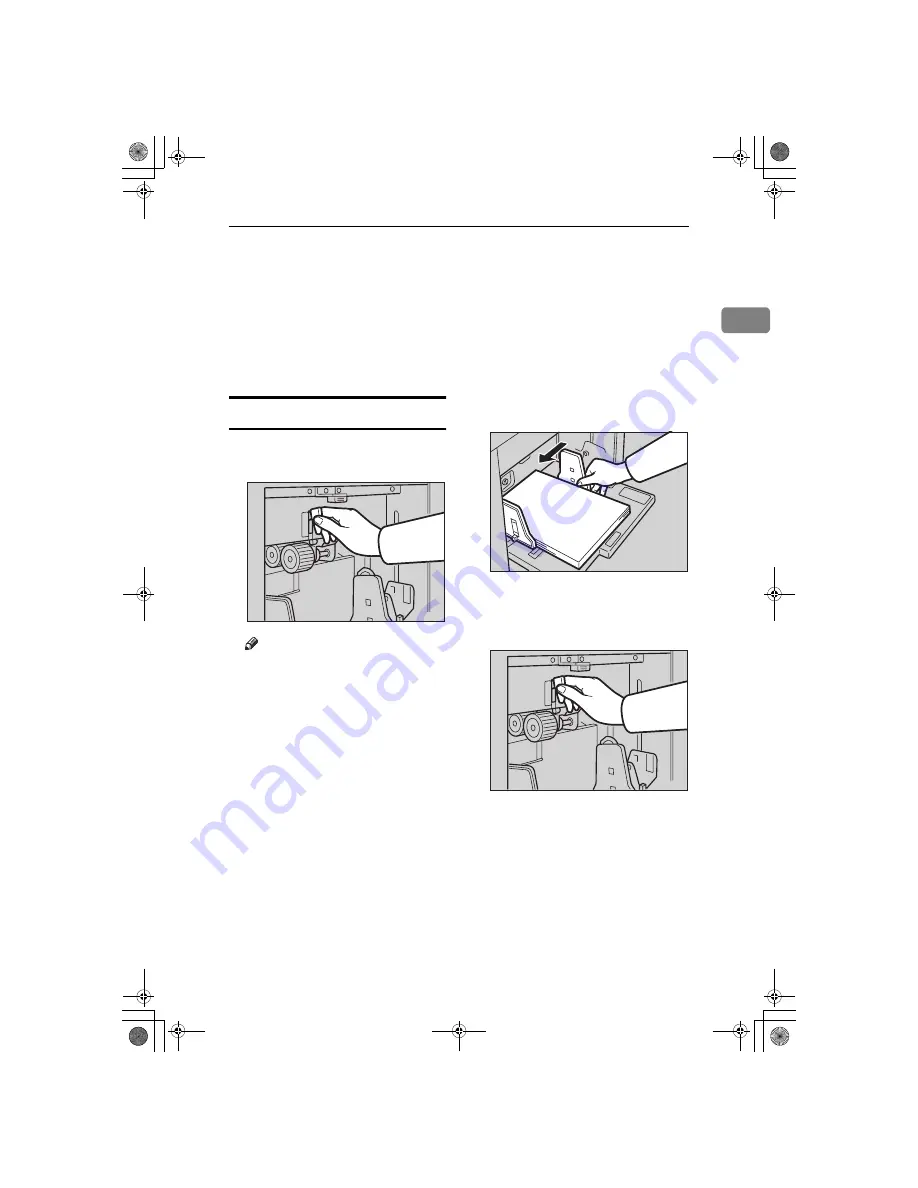

Pressure Lever Position

A

Position pressure lever to thick,

standard, or thin paper position.

Note

❒

When you use paper heavier

than 127.9g/m

2

, 34.0 lb and

lighter than 209.3g/m

2

, 55.6 lb,

position pressure lever to the

Thick paper position.

❒

When you use paper heavier

than 52.3g/m

2

, 13.9 lb and light-

er than 127.9g/m

2

, 34.0 lb, posi-

tion pressure lever to the

Standard paper position.

❒

When you use paper heavier

than 47.1g/m

2

, 12.5 lb and light-

er than 52.3g/m

2

, 13.9 lb, posi-

tion pressure lever to the Thin

paper position.

❒

In the case of paper smaller than

B5, 5

1

/

2

"

×

8

1

/

2

" and heavier

than 81.4g/m

2

(21.6 lb), move

the feed roller pressure lever to

the Thin paper position.

B

Make sure that the paper feed

side plates touch the paper light-

ly.

C

When you finish prints, position

pressure lever to the Standard pa-

per position.

TSLH01CE

ZCTH150E

TSLH01CE

SilverV-EN.book Page 23 Monday, May 15, 2000 3:23 PM

Summary of Contents for Priport JP1030

Page 25: ...xviii This page is intentionally blank...

Page 93: ...SERVICE PROGRAM MODE 68 3 This page is intentionally blank...

Page 103: ...REPLENISHING SUPPLIES 78 4 This page is intentionally blank...

Page 148: ......

Page 168: ...xvi SilverV EN book Page xvi Monday May 15 2000 3 23 PM...

Page 224: ...Optional Functions 56 2 SilverV EN book Page 56 Monday May 15 2000 3 23 PM...

Page 240: ...Service Program Mode 72 3 SilverV EN book Page 72 Monday May 15 2000 3 23 PM...

Page 248: ...Replenishing Supplies 80 4 SilverV EN book Page 80 Monday May 15 2000 3 23 PM...

Page 284: ...Remarks 116 6 SilverV EN book Page 116 Monday May 15 2000 3 23 PM...

Page 357: ...Optional Functions 54 2...

Page 372: ...Master Roll Replacement 69 4 F F F F Close the plotter cover G G G G Push in the master tray...

Page 409: ...Remarks 106 6...

Page 418: ...115 MEMO...

Page 419: ...116 UE USA C238 MEMO...