COMPONENT LAYOUT

21 May, 1999

1-12

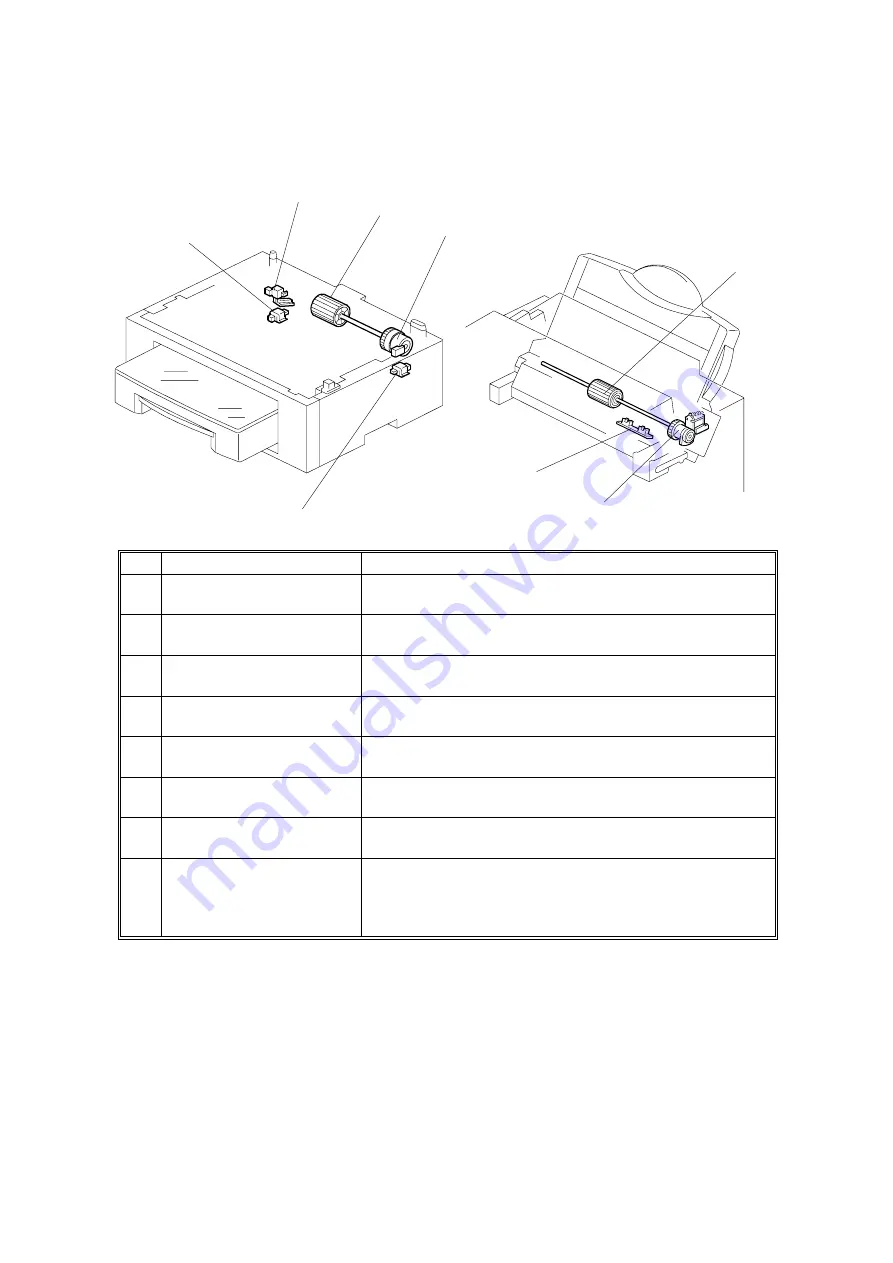

6. Optional Paper Feed Unit and Multi Purpose Feeder

No

Name

Description

1

Paper End Sensor

(Paper Feed Unit)

This detects when the paper in the cassette has run

out.

2

Paper Feed Roller

(Paper Feed Unit)

Picks up the top sheet of paper from the stack in the

cassette, and feeds it into the printer.

3

Paper Feed Clutch

(Paper Feed Unit)

Transfers drive from the paper feed motor in the

mainframe to the paper feed roller in the cassette.

4

Cassette Switch

(Paper Feed Unit)

This detects whether the cassette is installed or not.

5

Rear Cover Switch

(Paper Feed Unit)

This detects whether the rear cover is open or close.

6

Paper Feed Roller

(Multi-purpose Feeder)

Picks up the top sheet of paper from the stack in the

feeder, and feeds it into the printer.

7

Paper Feed Solenoid

(Multi-purpose Feeder)

Transfers drive from the paper feed motor in the

mainframe to the paper feed roller in the feeder.

8

Paper End Sensor and

Paper Width Sensor

(Multi-purpose Feeder)

Paper end sensor: This detects when the paper in the

feeder has run out.

Paper width sensor: This detects the paper width

installed in the feeder.

H547V516.WMF

H547V504.WMF

1

2

4

6

7

8

3

5