Description of the device

— 03.09.2020 - Rev. A

English — 5

4.3.2

Type code

No.

Reflexomat RS type key

1

Control unit

designation

2

Number of

compressors

Reflexomat RS 90 / 1, RG 1000 l, RF 1000 l

3

"RG" primary vessel

1 2 3 4 5

6

4

Nominal volume

5

"RF" secondary

vessel

6

Nominal volume

4.4

Function

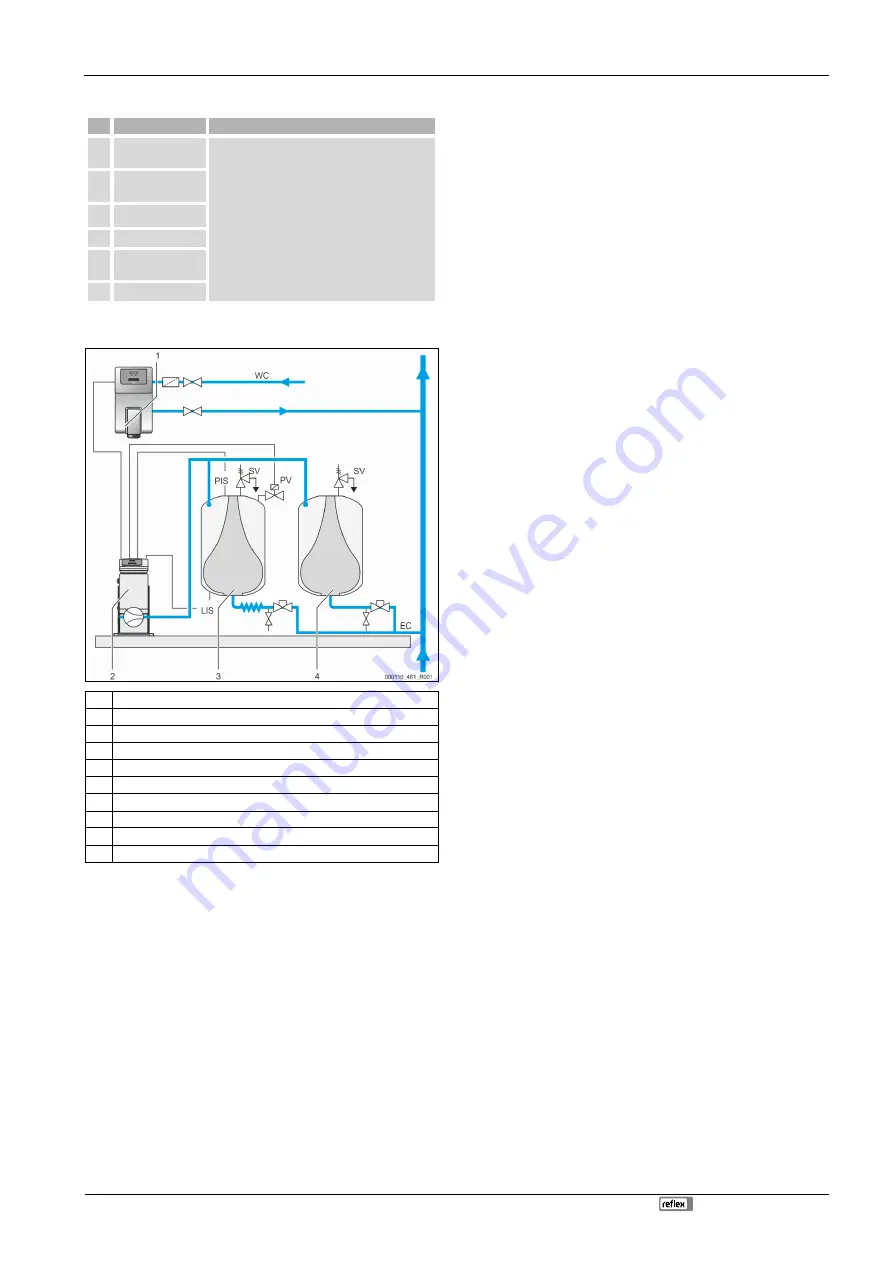

1

Make-up with water using "Fillcontroll Auto"

2

Control unit

3

Primary vessel as expansion vessel

4

Secondary vessel as additional expansion vessel

WC Make-up pipe

PIS Pressure sensor

SV

Safety valve

PV Solenoid valve

LIS Pressure load cell

EC

Expansion pipe

Expansion vessels

One primary vessel and multiple optional secondary vessels may be connected. A

membrane separates the vessels into an air and a water space, preventing the

penetration of atmospheric oxygen into the expansion water. The primary vessel

is connected to the control unit downstream and connected hydraulically to the

plant system. The pressure is protected at the air side by the "SV" safety valves of

the vessels.

Control unit

The control unit contains one or optionally two compressors "CO" and the "Reflex

Control Touch" controller. Via the primary vessel, the pressure is measured with

the "PIS" pressure sensor and the water level with the "LIS" pressure load cell

and the values then displayed in the controller display.

Pressurisation

•

If the water is heated, it expands and the pressure increases in the plant

system. If the pressure set at the controller is exceeded, the "PV" solenoid

valve opens and discharges air from the primary vessel. Water flows from

the system into the primary vessel and the pressure drops in the plant

system until the pressure in the plant system and the primary vessel is

equalised.

•

The pressure in the plant system drops when the water cools. When the

pressure drops below the set value, the "CO" compressor cuts in and

delivers compressed air into the primary vessel. This displaces water out of

the primary vessel into the plant system. The pressure in the facility system

rises.

Make-up

The addition of more water is controlled within the controller. The "LIS" pressure

load cell determines the water level and sends this value to the controller of the

pressure maintaining station. This controls an external make-up. Water is directly

added into the system in a controlled manner by monitoring the make-up time

and the make-up cycles.

If the water level in the primary vessel falls below minimum, a fault message is

output from the controller and shown in the display.

Note!

Additional equipment for topping up water, see chapter 4.6 "Optional

equipment and accessories" on page 5 .

4.5

Scope of delivery

The scope of delivery is described in the shipping document and the content is

shown on the packaging.

Immediately after receipt of the goods, please check the shipment for

completeness and damage. Please notify us immediately of any transport

damage.

Basic pressure-maintaining equipment:

•

Control unit with one or two compressor(s) including compressed air

line(s).

•

Primary tank with flexible water connection.

•

"LIS" pressure load cell for level sensing.

4.6

Optional equipment and accessories

•

Secondary vessels with connection sets for the primary vessel.

•

For make-up with water

–

Make-up without pump:

•

Solenoid "Fillvalve" with ball valve and Reflex Fillset for make-

up with drinking water.

–

Make-up with pump:

•

Reflex Fillcontrol Auto, with integrated pump and a system

separation vessel or Auto Compact

•

For make-up and degassing with water:

–

Reflex Servitec S

–

Reflex Servitec 35- 95

•

Fillset for make-up with drinking water.

–

With integrated system separator, water meter, dirt trap and locking

mechanisms for the "WC" make-up line.

•

Fillset Impulse with FQIRA+ contact water meter for make-up with

drinking water.

•

Fillsoft for softening or desalination of the make-up water from the

drinking water network.

–

Fillsoft is installed between Fillset and the device. The device

controller evaluates the make-up quantities and signals the required

replacement of the softening cartridges.

•

Optional expansions for Reflex controllers:

–

I/O module for standard communication, see chapter 5 "I/O module

(optional expansion module)" on page 6 .

–

Master-Slave-Connect for master controllers for maximum 10

devices.

–

Bus modules:

•

Profibus DP

•

Ethernet

•

Diaphragm rupture monitor

Note!

Separate operating instructions are supplied with accessories.

Cooke Industries - Phone: +64 9 579 2185 Email: [email protected] Web: www.cookeindustries.co.nz