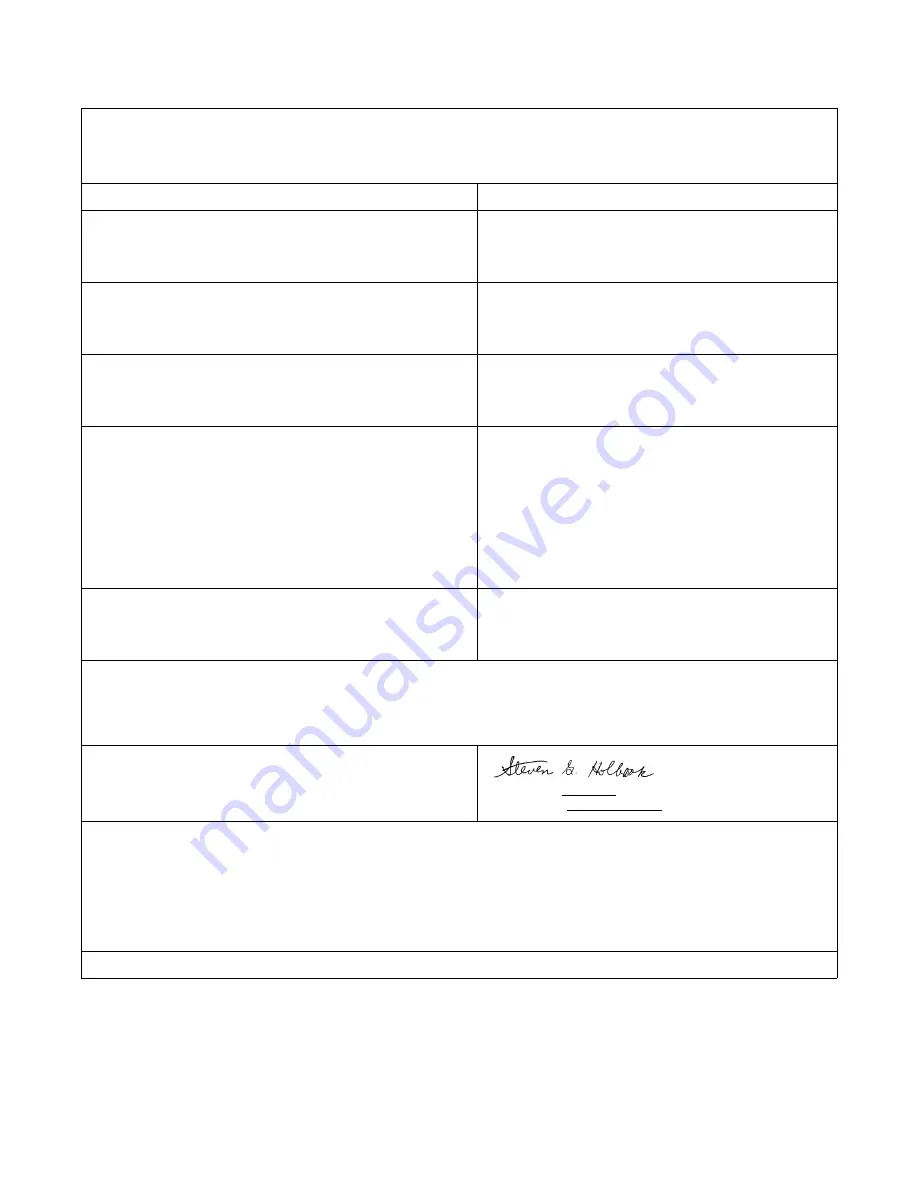

Declaration of Conformity

Declaration de Conformité

Ubereinstimmungserklärung

Dichiarazione di Conformità

ID

DoC-22834645

Manufacturer’s name and address

Nom et adresse du fabricant

Hersteller

Nome del costruttore

AstroNova, Inc.

600 East Greenwich Avenue

West Warwick, RI 02893 USA

Model No.

Modele No.

Model Nr.

Modello No.

Kiaro! 50

Description of Products

Description des produits

Produktbeschreibungen

Descrizione dei Prodotti

Color Label Printer

Standards to which conformity is declared

Standards auquel la conformité appartient

Normen für welche Übereinstimmung erklärt wird

Norme per le quali si dichiara la conformità

EN 60950-1:2006 /A11:2009 /A1:2010 /A12:2011 /A2:2013

EN 50564: 2011 (Commission Regulation (EC) No 1275/2008

and (EU) No 801/2013)

EN 50563:2011 (Commission Regulation (EC) No 278/2009)

EN 55032: 2012 Class B

EN 61000-3-2: 2014 Class A

EN 61000-3-3: 2013

EN 55024:2010

FCC Part 15B Class B

ICES-003 Class B

Application of Council Directives

Application des Decisions du Conseil

Anwendbar fur die Richtlinien

Applicazione delle Direttive del Comitato

2004/108/EC

2006/95/EC

2005/32/EC

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standard.

Je, Soussigné, déclare que l’équipment spécifié ci-dessus est en conformité avec la directive et le standard ci-dessus.

Ich, der unterzeichnende erkläre hiermit, daß das oben beschriebene Gerät den vorgenannten Richtlinien und Normen entspricht.

Il sottoscritto dichiara che l’apparecchio sopra specificato è conforme alle Direttive e Norme sopra specificate.

Steven Holbrook

Quality Assurance Manager

AstroNova, Inc.

Date of issue: 7/21/2016

Place of issue: West Warwick, RI

European Contact: Your local AstroNova, Inc. Sales and Service Office.

FRANCE - Parc Euclide, ZA la Clef de St Pierre, 10A Rue Blaise Pascal 78990 Elancourt

Tel: (+33) 1 34 82 09 00, Fax: (+33) 1 34 82 05 71

GERMANY - Senefelderstrasse 1/T6, D-63110 Rodgau

Tel. +49 (0) 6106-28368-20, Fax: +49 (0) 6106-771121

UNITED KINGDOM - 11 Whittle Parkway, Slough, Berkshire, SL1 6DQ

Tel: +44 (0)1628 668836, Fax: +44 (0)1628 664994

Ink Tanks and Maintenance Cartridge included

Summary of Contents for Kiaro! 50

Page 2: ......

Page 12: ......

Page 16: ...Contents iv Kiaro 50 User Guide...

Page 46: ...Introduction 30 Kiaro 50 User Guide...

Page 72: ...Designing and Printing Labels 56 Kiaro 50 User Guide...

Page 88: ...Kiaro 50 Maintenance Utility 72 Kiaro 50 User Guide...

Page 122: ...Troubleshooting 106 Kiaro 50 User Guide...

Page 128: ...Safety Warnings and Precautions 112 Kiaro 50 User Guide...