PowerFleet

®

VAC4 and VAC4S Hardware User’s Guide

085-00000700 Rev K

Page 24 of 103

VAC Synchronization

Wirelessly, using Intelligent RF (IRF)

When a successfully configured VAC comes within wireless coverage range of a Wireless Asset Manager (WAM), the VAC

will automatically synchronize its configuration with the PowerFleet Vision Pro software configuration. The first

synchronization may take 5 to 10 minutes, depending on the number of changes (added operators, groups, etc.) made in

Vision Pro software. Subsequent synchronizations may take from a few seconds to a minute.

Wirelessly, using Wi-Fi

When a successfully configured VAC (including Wi-

Fi profiles; see “Wi

-

Fi Configuration on the VAC”) comes within

wireless coverage range of a working and valid Access Point, the VAC will automatically synchronize its configuration

with the Vision Pro software. The first synchronization may take 5-10 minutes, depending on the number of changes

(added operators, groups, etc.) made in the Vision

Pro™

software. Subsequent synchronizations may take from a few

seconds to a minute.

Impact Sensor Configuration

There are 3 steps to achieving a functional impact management system once the impact sensor is properly physically

installed. Refer to the PowerFleet Installation Guide. Each step is automatic and designed to work out-of-the-box.

The

first step

is calibrating the impact sensor, which

relies on proper installation and mounting. The purpose

of the calibration is similar to resetting an empty scale to

zero pounds before weighing an object. A valid reference

point is needed. The calibration process is automatically

performed during the VAC Configuration process above.

Once that process is completed without errors, the

impact sensor has its initial calibration. The system then

automatically re-calibrates the sensor once per day

during periods of inactivity to make sure the environment

hasn’t changed (i.e. the

sensor came loose from the

mounting surface).

If a subsequent calibration attempt fails, a diagnostic

error is reported.

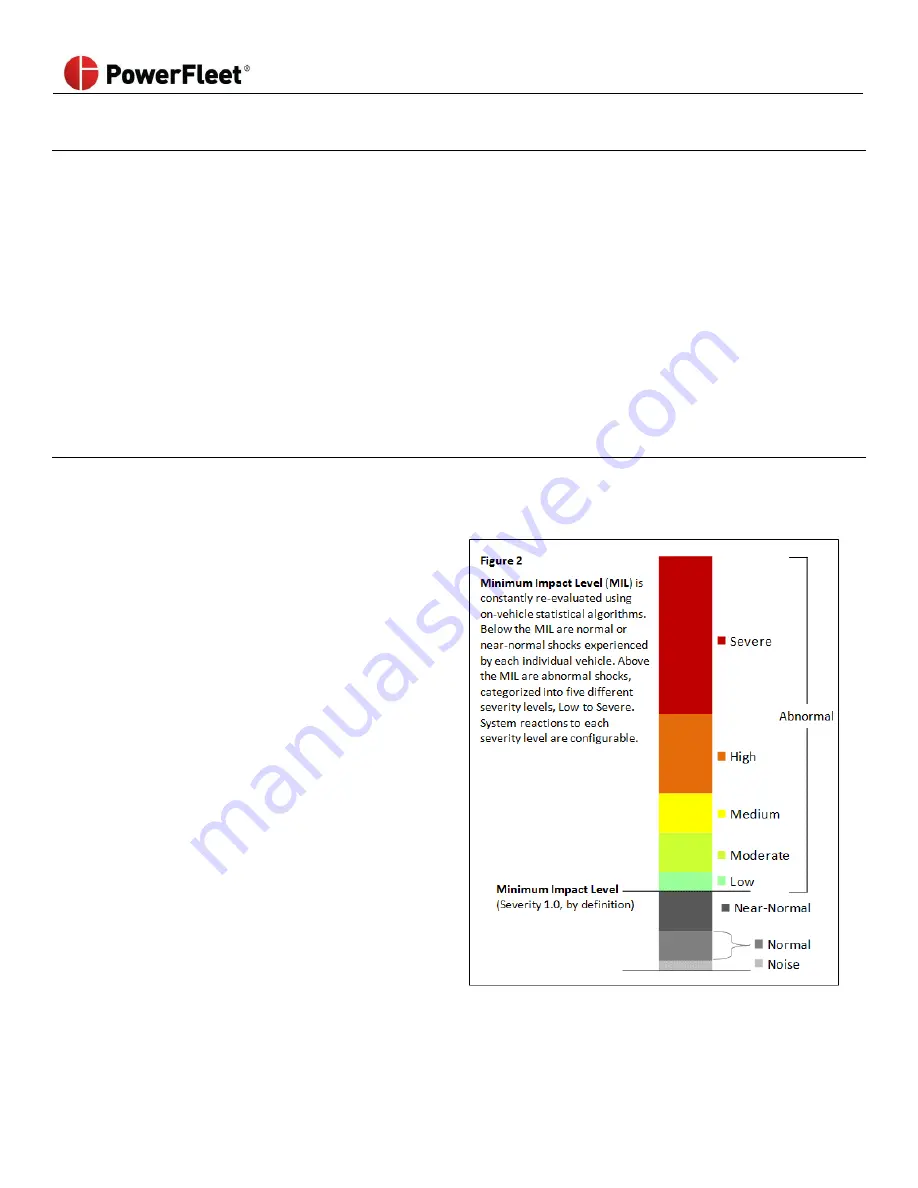

The

second step

is determining a valid Minimum Impact

Level (MIL) Threshold. The MIL quantifies the point

between “normal” and “abnormal” shock activity on each

individual vehicle, and forms the basis for defining the

relative severity of abnormal impacts. The MIL is an

automatically calculated point, based on continuous

evaluation of real-time impact data, which adjusts

automaticall

y to reflect the actual range of “normal”

shock activity on each vehicle as it changes over time

(due to different drivers, environments, tasks, etc.).

By definition, the MIL is assigned a Severity Level of 1.0, no matter how its calculated value fluctuates. Below this level,

shock activity is classified as Normal, Near-Normal, or simply Noise, and is not recorded in detail. Above the MIL, impacts