5-48

PFC-6030 • 5403595 • REV C-1 • 10/13

Uploading from Panel to Computer

The

Upload Configuration File to Computer transfer icon

is used to upload the configuration file from the panel to the

computer once the LEARN function is completed or whenever devices are added or removed from the panel.

To upload programming changes to computer:

1. Click the

Upload Configuration File to Computer icon

or right click from

“Transfers” region

as shown below:

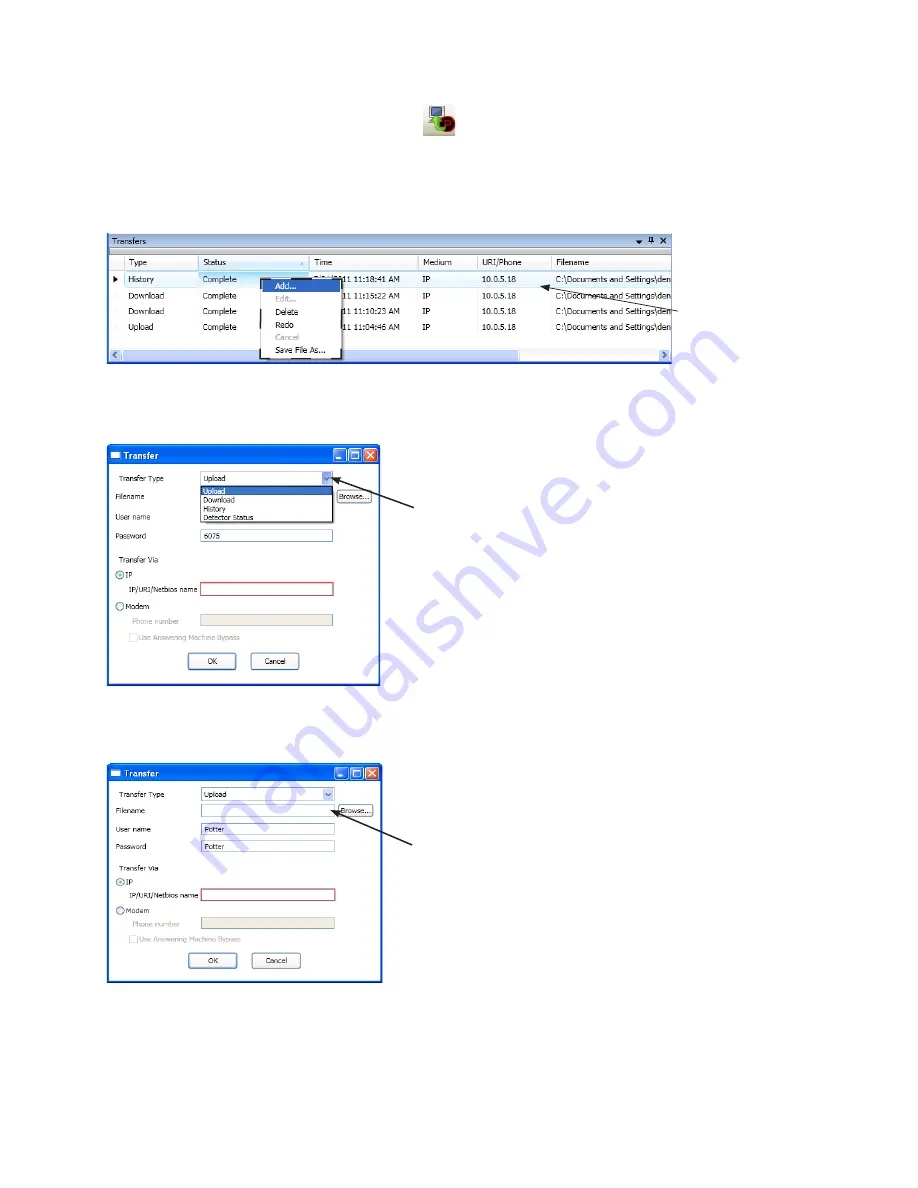

Figure 60. Example of Transfer Shortcut Menu

Note

: Click the

"Add" option

from the shortcut menu to choose the transfer type.

The

Transfer dialog box

displays.

Figure 61. Example of Transfer Upload Dialog Box

2. Verify that

Upload

is selected in the

“Transfer Type” field.

3. Enter the

configuration filename

in the

“Filename” field

or leave blank to Autoname.

Figure 62. Example of Transfer – Upload Window

Notes

:

•y

If you do not name the file, the program automatically names it using the transfer type and date stamp as the

file name.

•y

Once the file has been saved, and additional programming changes are made at a later date, click the

Browse button

to

locate the file name to replace the old file with the updated configuration changes.

Click here to choose applicable

transfer type, if necessary.

Enter file name or leave blank

to auto-name.

Right click anywhere in the

transfer window to display

the

shortcut menu.