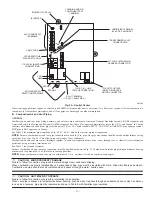

d. Insert assembled combustion-air inlet pipe into intake housing.

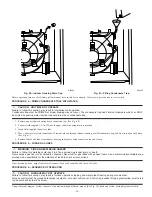

e. Make sure elbow is oriented in an acceptable direction and that the minimum clearance of 3 in. is observed. (See Fig. 50.)

f. Drill a 1/8-in. hole in 2-in. combustion-air inlet pipe using hole in intake housing as a guide.

g. Install a field-supplied No. 6 or No. 8 sheet metal screw into combustion-air pipe.

NOTE:

Do not attach combustion-air intake pipe permanently to combustion-air intake housing since it may be necessary to remove pipe for

service of igniter or flame sensor.

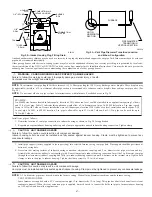

COMBUSTION-AIR INTAKE HOUSING PLUG FITTING

The combustion-air intake plug fitting must be installed in unused combustion-air intake housing. This fitting must be attached by using

RTV sealant, or by drilling a 1/8-in. hole in fitting, using hole in intake housing as a guide. Install a field-supplied No. 6 or No. 8 sheet

metal screw.

NOTE:

DO NOT OVERTIGHTEN SCREW. Breakage of intake housing or fitting may cause air leakage to occur.

A plugged drain connection has been provided on this fitting for use when moisture is found in combustion-air intake pipe and combustion

box. If use of this drain connection is desired, drill out fitting’s tap plug with a 3/16-in. drill and connect a field-supplied 3/8-in. tube. This

tube should be routed to open condensate drain for furnace and A/C (if used), and should be trapped. (See Fig. 52.)

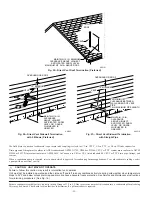

VENT PIPE

NOTE:

Furnace vent pipe connections are sized for 2-in. pipe. Any vent pipe size change should be made outside furnace casing in vertical pipe.

(See Fig. 53.) This allows proper drainage of vent condensate.

Determine vent pipe diameter and maximum pipe lengths using Table 11.

Furnace vent pipe connection must be attached as shown in Fig. 50. Inducer housing alternate vent cap may need to be relocated in some

applications.

NOTE:

Starting at furnace, slope vent pipe a minimum of 1/4 in. per linear ft upward to termination(s) with no sags between hangers.

CAUTION: UNIT MAY NOT OPERATE

Failure to follow this caution may result in intermittent unit operation.

When vent pipe is exposed to temperatures below freezing, such as when it passes through an unheated space or when a chimney

is used as a raceway, pipe must be insulated as described in Table 10 with Armaflex-type insulation.

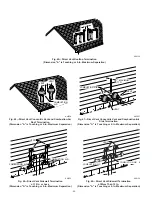

Fig. 50—Combustion-Air and Vent Pipe Connections

CAUTION: UNIT MAY NOT OPERATE

Failure to follow this caution may result in intermittent unit

operation.

Make sure there is adequate clearance (3-in. minimum) to any

fixed or loose objects in order to ensure an adequate

combustion-air supply.

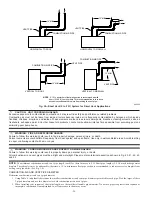

A96188

COMBUSTION-

AIR

COMBUSTION-

AIR

AIR

FLOW

VENT

VENT

VENT

AIR

FLOW

AIR

FLOW

AIR

FLOW

UPFLOW

DOWNFLOW

HORIZONTAL-LEFT DISCHARGE

HORIZONTAL-RIGHT DISCHARGE

Select 1 vent pipe connection and

1 combustion-air pipe connection.

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

COMBUSTION-

AIR

NOTE:

Select 1 vent pipe connection and

1 combustion-air pipe connection.

NOTE:

VENT

VENT

VENT

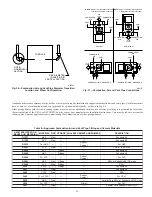

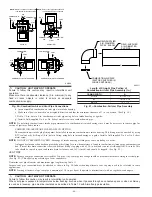

Fig. 51—Combustion-Air Inlet Pipe Assembly

Length of Straight Pipe Portion of

Combustion-Air Inlet Pipe Assembly (In.)

CASING WIDTH

A

17-1/2

8-1/2

±

1/2

21

10-1/2

±

1/2

24-1/2

12

±

1/2

A96211

FIELD-SUPPLIED

2-IN. DIAMETER

PVC PIPE

FIELD-SUPPLIED

2-IN. DIAMETER

PVC 90

°

ELBOW

COMBUSTION-AIR DISC

(FACTORY-SUPPLIED IN

LOOSE PARTS BAG)

A

—46—

Summary of Contents for PG9MAA

Page 70: ... 70 ...

Page 71: ... 71 ...