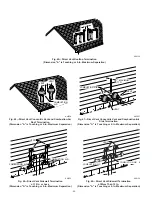

An abandoned masonry chimney may be used as a raceway for a properly insulated and supported vent pipe. Each furnace must have its own vent

pipe and be terminated individually.

Other gas appliances with their own venting system may also use the abandoned chimney as a raceway providing it is permitted by local code,

the current edition of the NFGC or NSCNGPIC, and the vent or liner manufacturer’s Installation Instructions. Care must be taken to prevent the

exhaust gases from one appliance from contaminating the combustion air of other gas appliances.

WARNING: CARBON MONOXIDE AND PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in property damage, personal injury, or death.

Vent pipes must be airtight and watertight.

NOTE:

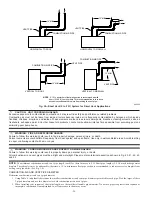

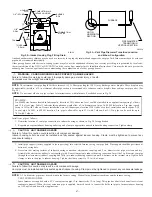

The minimum vent pipe length for these furnaces is 5 ft. Short pipe lengths (5-8 ft) may discharge water droplets. These droplets may

be undesirable; therefore, a 12-in. minimum offset pipe section is recommended to reduce excessive droplets from exiting vent pipe outlet. (See

Fig. 54.)

NOTE:

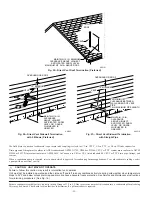

Do not count elbows or pipe sections in terminations or within furnace. See shaded areas in Fig. 56.

EXAMPLE:

An 036080 size furnace located in Indianapolis, elevation 650 ft above sea level, could be installed in an application requiring 3 elbows

and 32 ft of vent pipe. Table 11 indicates this application would allow a 2-in. diameter vent pipe. At 0-2000 ft elevation, 2-in. pipe is good

for up to 35 ft with 3 elbows. If same installation were in Albuquerque, elevation 5250 ft above sea level, installation would require 2-1/2

in. vent pipe. At 5001- to 6000-ft elevation, 2-in. pipe is allowed for up to 23 ft with 3 elbows, but 2-1/2 in. pipe can be used for up to

70 ft with 3 elbows.

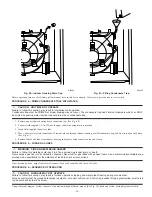

Install vent pipe as follows:

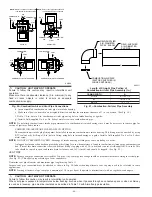

1. Determine location of vent pipe connection to inducer housing as shown in Fig. 50 for application.

2. Reposition neoprene inducer housing outlet cap and clamp to appropriate unused inducer housing connection. Tighten clamp.

CAUTION: UNIT DAMAGE HAZARD

Failure to follow this caution could result in unit component damage.

Inducer housing outlet cap must be installed and fully seated against inducer housing. Clamp must be tightened to prevent any

condensate leakage.

3. Install pipe support (factory-supplied in loose parts bag) into selected furnace casing vent pipe hole. Pipe support should be positioned at

bottom of casing hole.

4. Be certain that mating surfaces of inducer housing connection, elastomeric coupling, and 2-in. diameter vent pipe are clean and dry.

Assemble the elastomeric (rubber) vent coupling (with 2 loose clamps) onto inducer housing connection. Insert the 2-in. diameter vent pipe

through the elastomeric (rubber) coupling and fully into inducer housing connection until it bottoms on the internal stop. Tighten both

clamps to secure the pipe to inducer housing. Tighten the clamp screws to 15 in.-lb. of torque.

CAUTION: UNIT DAMAGE HAZARD

Failure to follow this caution may result in unit component damage.

Vent pipe must be installed and fully seated against inducer housing. Clamp must be tightened to prevent any condensate leakage.

NOTE:

A 2-in. diameter pipe must be used within the furnace casing. Make all pipe diameter transitions outside furnace casing.

VENT EXTENSION PIPE

Some furnaces are supplied with a PVC vent extension pipe (2-in. diameter by 12-in. long). This pipe has a built-in channel to assist vent

condensate disposal. When this vent extension pipe is supplied, it must be used to connect the field vent pipe to furnace inducer housing

on ALL upflow and downflow applications.

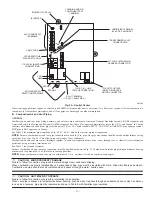

Fig. 52—Intake Housing Plug Fitting Drain

A96190

COMBUSTION–

AIR PIPE

BURNER

BOX

COMBUSTION–AIR

INTAKE HOUSING

3/8

″

ID TUBE

TRAP

TO OPEN

DRAIN

3/16

″

DRILL

HOUSING

PLUG

4

″

MIN

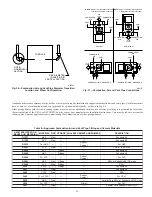

Fig. 53—Vent Pipe Diameter Transition Location

and Elbow Configuration

A93034

FURNACE

PIPE DIAMETER

TRANSITION IN

VERTICAL SECTION

NOT IN

HORIZONTAL

SECTION

—47—

→

→

Summary of Contents for PG9MAA

Page 70: ... 70 ...

Page 71: ... 71 ...