B.

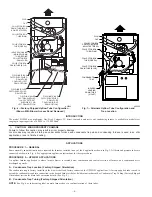

Condensate Trap Tubing

NOTE:

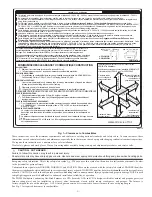

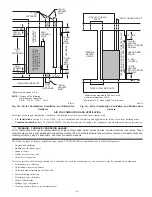

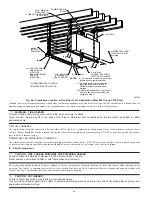

See Fig. 8 or 9 or tube routing label on main furnace door to check for proper connections.

1. Collector Box Drain Tube

a. Remove factory-installed plug from LOWER collector box drain tube (blue and white striped label).

b. Install removed clamp and plug into UPPER collector box drain tube (blue label) which was connected to condensate trap.

c. Connect LOWER collector box drain connection to condensate trap.

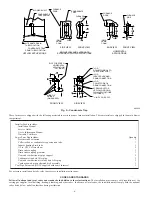

Condensate Trap Located on Left Side of Casing

(1.) Connect LOWER collector box drain tube (blue and white striped label) to condensate trap. Tube does not need to be cut.

(2.) Clamp tube to prevent any condensate leakage.

Condensate Trap Located on Right Side of Casing

(1.) Install drain tube coupling (factory-supplied in loose parts bag) into collector box drain tube (blue and white striped label) which

was previously plugged.

(2.) Connect larger diameter drain tube (factory-supplied in loose parts bag) to drain tube coupling, extending collector box drain tube

for connection to condensate trap.

(3.) Route extended collector box drain tube directly from collector box drain to condensate trap as shown in Fig. 9.

(4.) Determine appropriate length and cut.

(5.) Connect to condensate trap.

(6.) Clamp tube to prevent any condensate leakage.

2. Inducer Housing Drain Tube

a. Remove factory-installed cap and clamp from LOWER inducer housing drain connection.

b. Remove and discard UPPER (molded) inducer housing drain tube which was previously connected to condensate trap.

c. Install cap and clamp on UPPER inducer housing drain connection where molded drain tube was removed.

d. Use inducer housing drain tube (violet label and factory-supplied in loose parts bag) to connect LOWER inducer housing drain

connection to the condensate trap.

e. Connect inducer housing drain connection to condensate trap.

Condensate Trap Located on Left Side of Casing

(1.) Determine appropriate length and cut.

(2.) Connect tube to condensate trap.

(3.) Clamp tube to prevent any condensate leakage.

Condensate Trap Located on Right Side of Casing

(1.) Route inducer housing drain tube (violet label) directly from inducer housing to condensate trap as shown in Fig. 9.

(2.) Determine appropriate length and cut.

(3.) Connect tube to condensate trap.

(4.) Clamp tube to prevent any condensate leakage.

3. Relief Port Tube

Refer to Pressure Switch Tubing section for connection procedure.

C.

Condensate Trap Field Drain Attachment

Refer to Condensate Drain section for recommendations and procedures.

D.

Pressure Switch Tubing

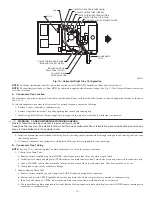

One collector box pressure tube (pink label) is factory connected to the pressure switch for use when furnace is installed in UPFLOW applications.

This tube MUST be disconnected and used for the condensate trap relief port tube. The other collector box pressure tube (green label) which was

factory connected to the condensate trap relief port connection MUST be connected to the pressure switch in DOWNFLOW or HORIZONTAL

RIGHT applications.

NOTE:

See Fig. 8 or 9 or tube routing label on main furnace door to check for proper connections.

Relocate tubes as described below.

1. Disconnect collector box pressure tube (pink label) attached to pressure switch.

2. Extend collector box pressure tube (green label) which was previously connected to condensate trap relief port connection by splicing to

small diameter tube (factory-supplied in loose parts bag).

3. Connect collector box pressure tube (green label) to pressure switch connection labeled COLLECTOR BOX.

4. Extend collector box pressure tube (pink label) which was previously connected to pressure switch by splicing to remaining small diameter

tube (factory-supplied in loose parts bag).

5. Route this extended tube (pink label) to condensate trap relief port connection.

—11—

Summary of Contents for PG9MAA

Page 70: ... 70 ...

Page 71: ... 71 ...