E.

Component Test

NOTE:

The furnace control component test allows all components to run for a short time; except the gas valve and humidifier terminal HUM

are not energized for safety reasons. The EAC-1 terminal is energized when the blower is energized. This feature helps diagnose a system problem

in case of a component failure. The component test feature will not operate if any thermostat signal is present ant the control and not until all time

delays are completed.

NOTE:

Record the status code BEFORE opening the blower access door and before shutting off power to the furnace. Opening the blower

access door will open the blower door switch and shut off power within the furnace. When power to the furnace is shut off by either method, the

status code will be lost because the code is not stored while power is removed for any reason.

To Begin Component Self-Test:

WARNING: ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in electrical shock, personal injury, or death.

Blower access panel door switch opens 115-v power to control center. No component operation can occur. Caution must be taken

when manually closing this switch for service purposes.

1. Remove blower access door.

2. Disconnect the thermostat R lead from furnace control.

3. Manually close blower door switch.

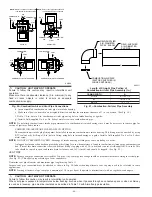

4. For approximately 2 sec, short (jumper) the C

OM

-24v terminal on control to the TEST/TWIN 3/16-inch quick-connect terminal on control

until the LED goes out. Remover jumper from terminals. (See Fig. 35.)

NOTE:

If TEST/TWIN and C

OM

-24v terminals are jumpered longer than 2 sec, LED will flash rapidly and ignore component test status code

retrieval request.

Component test sequence is as follows:

a. LED will display previous status code 4 times.

b. Inducer motor starts and continues to run until Step f of component test sequence.

c. After 7 seconds the hot surface igniter is energized for 15 sec, then off.

d. Blower motor operates on HEAT speed for 10 sec.

e. Blower motor operates on COOL speed for 10 sec.

f. Inducer motor stops.

5. Reconnect R lead to furnace control, remove tape from blower door switch, and re-install blower door.

6. Operate furnace per instruction on outer door.

7. Verify furnace shut down by lowering thermostat setting below room temperature.

8. Verify that furnace restarts by raising thermostat setting above room temperature.

PROCEDURE 5—ADJUSTMENTS

A.

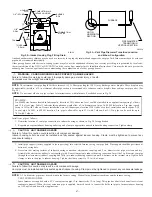

Set Gas Input Rate

Furnace gas input rate on rating plate is for installations at altitudes up to 2000 ft.

In the U.S.A., the input ratings for altitudes above 2000 ft must be reduced by 2 percent for each 1000 ft above sea level.

In Canada, the input ratings must be derated by 5 percent for altitudes of 2000 ft to 4500 ft above sea level.

Furnace input rate must be within

±

2 percent of input on furnace rating plate adjusted for altitude.

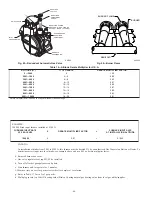

1. Determine natural gas orifice size and manifold pressure for correct input.

a. Obtain average gas heat value (at installed altitude) from local gas supplier.

b. Obtain average gas specific gravity from local gas supplier.

c. Verify furnace model and size. Table 12 can only be used for model PG9MAA furnaces with heating sizes of 040 through 120. Table

15 can only be used for model PG9MAA furnaces with heating size of 140.

d. Find installation altitude in Table 14 or 15.

NOTE:

For Canada altitudes of 2001 to 4500 ft, use U.S.A. altitudes of 2001 to 3000 ft in Table 14 or 15.

e. Find closest natural gas heat value and specific gravity in Table 14 or 15.

f. Follow heat value and specific gravity lines to point of intersection to find orifice size and manifold pressure settings for proper operation.

—57—

Summary of Contents for PG9MAA

Page 70: ... 70 ...

Page 71: ... 71 ...