3. Adjust temperature rise by adjusting blower speed. Increase blower speed to reduce temperature rise. Decrease blower speed to increase

temperature rise.

WARNING: ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Disconnect 115-v electrical power before changing speed tap.

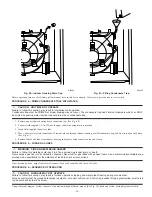

4. To change blower motor speed selections for heating mode, remove blower motor lead from control center HEAT terminal. (See Fig. 35.)

Select desired blower motor speed lead from 1 of the other motor leads and relocate it to HEAT terminal. See Table 18 for lead color

identification. Reconnect original lead on SPARE terminal.

Follow this same procedure for proper selection of COOL speed selection.

C.

Blower Off Delay (Heat Mode)

The blower off delay has 4 adjustable settings from 90 sec to 180 sec. (See Table 19.) The blower off delay jumpers are located on the furnace

control board (See Fig. 35). To change the blower off delay setting, move the jumper from one set of pins on the control board to the pins used

for the desired blower off delay. Factory blower off delay setting is 120 sec.

D.

Set Thermostat Heat Anticipator

When using a nonelectronic thermostat, the thermostat heat anticipator must be set to match amp draw of the electrical components in R-W circuit.

Accurate amp draw readings can be obtained at thermostat subbase terminals R and W. Fig. 65 illustrates an easy method of obtaining actual amp

draw. The amp reading should be taken after blower motor has started and furnace is heating. Connect ammeter wires as shown in Fig. 65. The

thermostat anticipator should NOT be in the circuit while measuring current. If thermometer has no subbase, the thermostat must be disconnected

from R and W wires during current measurement. See thermostat manufacturer’s instructions for adjusting heat anticipator and for varying heating

cycle length.

For an electronic thermostat, set cycle rate for 3 cycles per hour.

PROCEDURE 6—CHECK SAFETY CONTROLS

This section covers the safety controls that must be checked before installation is complete. The flame sensor, gas valve, and pressure switch were

all checked in the Start-up procedure section as part of normal operation.

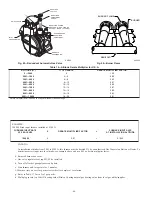

Table 18—Speed Selector

COLOR

SPEED

FACTORY-SHIPPED

CONNECTION

Black

High

Cool

Yellow (When Present)

Medium High

Spare

Blue

Medium Low

Heat

Red

Low

Spare

White

Common

Com

Fig. 65—Amp Draw Check with Ammeter

A80201

R

Y W G

10 TURNS

THERMOSTAT SUBBASE

TERMINALS WITH

THERMOSTAT REMOVED

HOOK-AROUND

VOLT/AMMETER

EXAMPLE:

5.0 AMPS ON AMMETER

10 TURNS AROUND JAWS

= 0.5 AMPS FOR THERMOSTAT SETTING

FROM UNIT 24-VOLT

TERMINAL BLOCK

—66—

Summary of Contents for PG9MAA

Page 70: ... 70 ...

Page 71: ... 71 ...