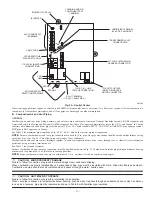

If pressure exceeds 0.5 psig (14-in. wc), gas supply pipe must be disconnected from furnace and capped before pressure test. If test pressure is

equal to or less than 0.5 psig (14-in. wc), turn off electric shutoff switch located on furnace gas valve and accessible manual shutoff valve before

test.

The gas supply pressure shall be within the maximum and minimum inlet supply pressures marked on the rating plate with the furnace burners

ON and OFF.

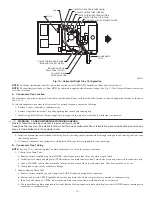

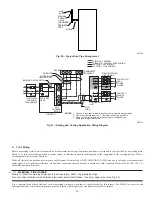

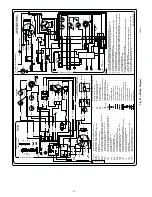

PROCEDURE 5—ELECTRICAL CONNECTIONS

See Fig. 31 for field wiring diagram showing typical field 115-v and 24-v wiring. Check all factory and field electrical connections for tightness.

Field-supplied wiring shall conform with the limitations of 63°F (35°C) rise.

WARNING: ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in serious injury or death.

Blower access panel door switch opens 115-v power to control center. No component operation can occur. Do not bypass or close

switch with panel removed.

CAUTION: FURNACE MAY NOT OPERATE

Failure to follow this caution may result in furnace operation stopping and water pipes freezing during cold weather.

Furnace control must be grounded for proper operation or control will lock out. Control is grounded through green/yellow wire routed

to gas valve and burner box screw.

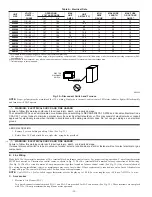

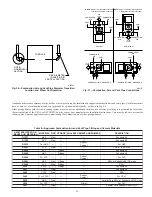

Table 5—Maximum Capacity of Pipe*

NOMINAL IRON PIPE SIZE

(IN.)

INTERNAL DIAMETER

(IN.)

LENGTH OF PIPE (FT)

10

20

30

40

50

1/2

0.622

175

120

97

82

73

3/4

0.824

360

250

200

170

151

1

1.049

680

465

375

320

285

1-1/4

1.380

1400

950

770

660

580

1-1/2

1.610

2100

1460

1180

990

900

* Cubic ft of gas per hr for gas pressures of 0.5 psig (14-in. wc) or less, and a pressure drop of 0.5-in. wc (based on a 0.60 specific gravity gas).

Ref: Table 9.2 NFPA 54-2002

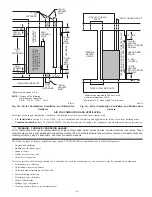

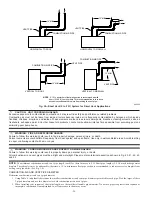

Fig. 27—Bottom Filter Arrangement

A00290

WASHABLE

FILTER

FILTER

SUPPORT

FILTER

RETAINER

17

1

⁄

2

-IN. WIDE

CASINGS ONLY:

INSTALL FIELD-SUPPLIED

FILTER FILLER STRIP

UNDER FILTER.

1

″

24

1

/

2

″

3

″

21-IN. WIDE

CASINGS ONLY:

SUPPORT RODS (3)

EXTEND 1/4" ON EACH

SIDE OF FILTER AND

REST ON CASING FLANGE

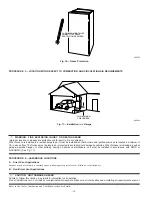

Fig. 29—Removing Bottom Closure Panel

A93047

BOTTOM

CLOSURE

PANEL

FRONT FILLER

PANEL

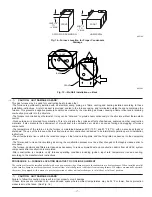

Fig. 28—Filter Installed for Side Inlet

A00217

—28—

Summary of Contents for PG9MAA

Page 70: ... 70 ...

Page 71: ... 71 ...