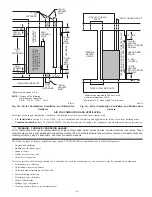

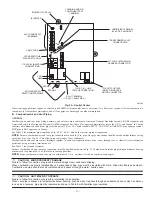

Direct venting applications require a dedicated (one PG9MAA furnace only) direct vent system. In a direct vent system, all air for combustion is

taken directly from outdoor atmosphere, and all flue gases are discharged to outdoor atmosphere.

B.

Combustion-Air and Vent Piping

GENERAL

Combustion-air and vent pipe, fittings, primers, and solvents must conform to American National Standards Institute (ANSI) standards and

American Society for Testing and Materials (ASTM) standards. See Table 8 for approved materials for use in the U.S.A. and Canada. In Canada

construct all combustion-air and vent pipes for this unit of CSA or ULC listed schedule-40 PVC, PVC-DWV or ABS-DWV pipe and pipe cement.

SDR pipe is NOT approved in Canada.

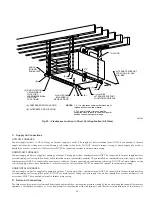

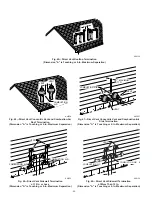

See Table 9 for maximum pipe lengths and Fig. 40, 41, 42, 43, and 44 for exterior piping arrangements.

NOTE:

Furnace combustion-air and vent pipe connections are sized for 2-in. pipe. Any pipe size change should be made outside furnace casing

in vertical pipe. (See Fig. 36.) This allows proper drainage of vent condensate.

Combustion-air and vent pipes must terminate together in same atmosphere pressure zone, either through roof or sidewall (roof termination

preferred), using accessory termination kit.

See Table 7 for required clearances.

Furnace combustion-air and vent pipe connections must be attached as shown in Fig. 37. Combustion-air intake plug fitting and inducer housing

alternate vent cap may need to be relocated in some applications.

NOTE:

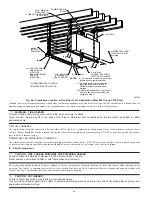

Slope combustion-air and vent pipes a minimum of 1/4 in. per linear ft with no sags between hangers.

CAUTION: MINOR PROPERTY DAMAGE

Failure to follow this caution may result in water damage from condensate dripping.

When combustion-air pipe is installed above a suspended ceiling, pipe must be insulated with 3/8-in. thick Armaflex-type insulation.

Combustion-air pipe should also be insulated when it passes through a warm, humid space.

CAUTION: UNIT MAY NOT OPERATE

Failure to follow this caution may result in intermittent unit operation.

When vent pipe is exposed to temperatures below freezing, such as when it passes through an unheated space or when a chimney

is used as a raceway, pipe must be insulated as shown in Table 8 with Armaflex-type insulation.

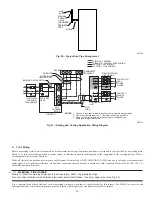

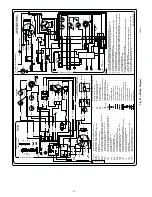

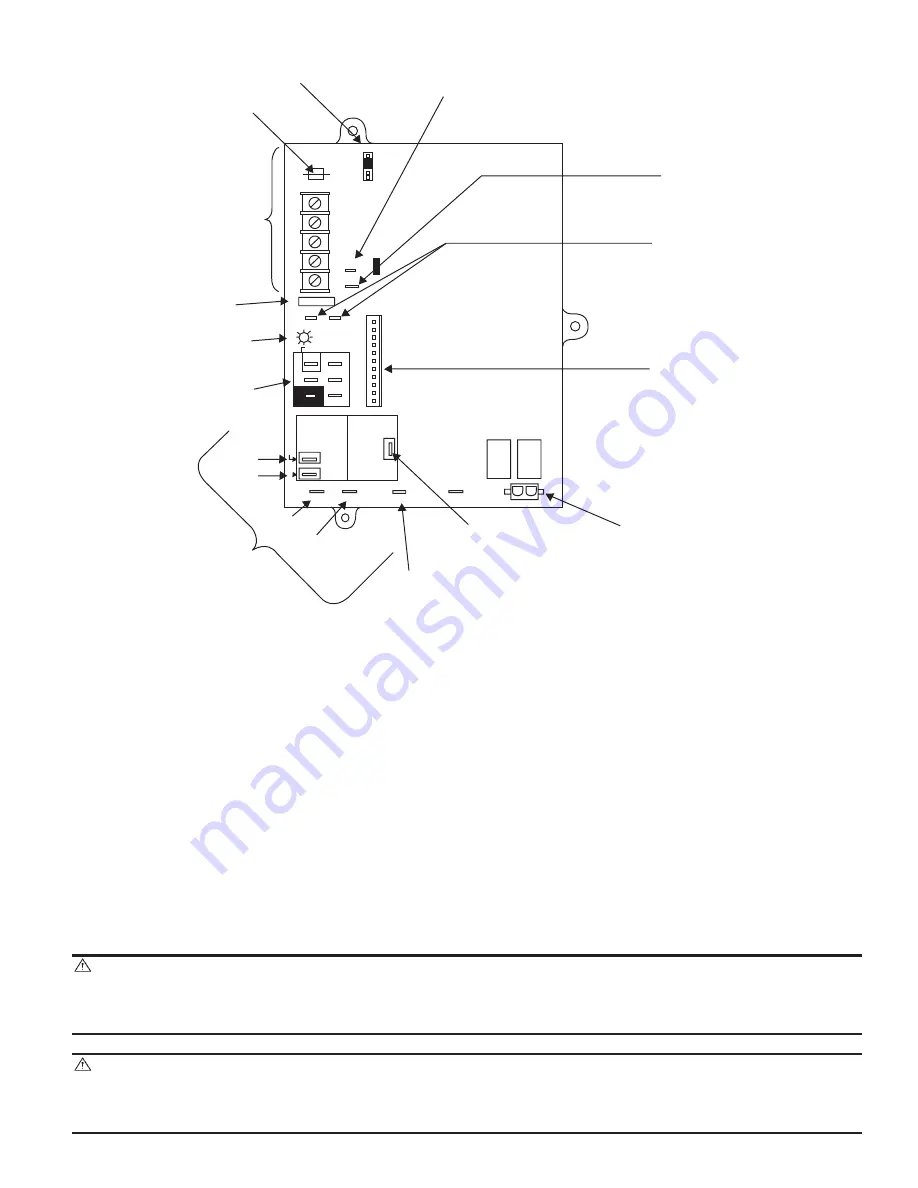

Fig. 35—Control Center

A02100

BL

W

NUETRAL

ST

A

TUS CODE LED

SEC-2 SEC-1

EAC-2 L2

FUSE 3-AMP

0.5 AMP@24VAC

HUM

TEST/TWIN

G Com

W

Y R

24V

120 180

90 150

BLOWER OFF-DELAY

PL

T 1

COOL HEA

T

SPARE-1 SPARE-2

EAC-1

1-AMP@

115VAC

PR-1

L1

PL2 1

24-V THERMOSTAT

TERMINALS

3-AMP FUSE

LED OPERATION &

DIAGNOSTIC LIGHT

115-VAC(L2)NEUTRAL

CONNECTIONS

COOL

HEAT

SPARE-1

SPARE-2

BLOWER SPEED

SELECTION TERMINALS

EAC-1 TERMINAL

(115-VAC 1.0 AMP MAX.)

115 VAC (L1) LINE

VOLTAGE CONNECTION

PL2-HOT SURFACE

IGNITER & INDUCER

MOTOR CONNECTOR

PL1-LOW VOLTAGE MAIN

HARNESS CONNECTOR

TRANSFORMER 24-VAC

CONNECTIONS

HUMIDIFIER TERMINAL

(24-VAC 0.5 AMP MAX.)

TWINNING AND/OR

COMPONENT TEST

TERMINAL

BLOWER OFF-DELAY

J2

J2 JUMPER

PL

T

—33—

Summary of Contents for PG9MAA

Page 70: ... 70 ...

Page 71: ... 71 ...