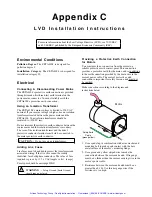

Appendix B

U s i n g N o n - C o m p u m o t o r M o t o r s

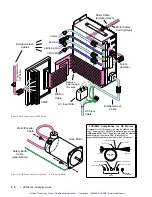

We recommend that you use Compumotor motors with the ZETA6104. If you use a non-

Compumotor motor, it must meet the following requirements:

¥ Inductance: 0.5 mH minimum; 5.0 to 50.0 mH recommended range; 80.0 mH maximum.

¥ A minimum of 500VDC high-pot insulation rating from phase-to-phase and phase-to-ground.

¥ The motor must be designed for use with a bipolar drive (no common center tap).

¥ The motor must not have riveted rotors or stators.

¥ Do not use solid rotor motors.

¥ Test all motors carefully. Verify that the motor temperature in your application is within the

system limitations.

The motor manufacturerÕs maximum allowable motor case temperature

must not be exceeded.

You should test the motor over a 2-to-3 hour period. Motors tend to

have a long thermal time constant, but can still overheat, which results in motor damage.

CAUTION

: Consult your motor vendor to verify that your motor meets the above

specifications. If you have questions regarding the use of a non-Compumotor motor with the

ZETA6104, consult your local Automation Technology Center (ATC) or distributor, or refer to

the numbers listed under

Technical Assistance

on the inside front cover of this document.

Wiring Configurations

Refer to the manufacturerÕs motor specification document

to determine the motorÕs wiring configuration. You can

also determine the wiring configuration with an ohmmeter

using the procedures below (

4-Lead Motor, 6-Lead Motor,

8-Lead Motor

). Once you determine the correct motor

wiring configuration, use the terminal connection diagram,

shown at the end of this section, that applies to your

configuration.

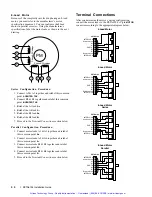

4-Lead Motor

1. Label one motor lead

A+

.

2. Connect one lead of an ohmmeter to the

A+

lead and

touch the other lead of the ohmmeter to the three

remaining motor leads until you find the lead that

creates continuity. Label this lead

AÐ

.

3. Label the two remaining leads

B+

and

BÐ

.

Verify that

there is continuity between the

B+

and

BÐ

leads

.

4. Proceed to the

Terminal Connections

section below.

6-Lead Motor

1. Determine, with an ohmmeter, which three of the six

motor leads are common (one phase).

2. Label each one of these three motor leads

A

.

3. Using the ohmmeter, verify that the remaining three

leads are common.

4. Label the remaining three leads

B

.

5. Set the ohmmeter range to the 100 ohm scale

(approximately).

6. Connect the ohmmeterÕs negative lead to one of the

motor leads labeled

A

. Alternately measure the

resistance to the two remaining motor leads also

labeled

A

. The resistance measurements will reflect

one of the following two scenarios.

Scenario #1

Ñ The resistance measurements to

the two remaining motor leads are virtually identical.

Label the two remaining motor leads

A+

and

AÐ

.

Label the motor lead connected to the negative lead

of the ohmmeter

AÊCENTER TAP

(this is the center

tap lead for Phase A of the motor).

Scenario #2

Ñ The resistance measurement to the

second of the three motor leads measures 50% of the

resistance measurement to the third of the three

motor leads. Label the second motor lead

AÊCENTER

TAP

(this is the center tap lead for Phase A of the

motor). Label the third motor lead

AÐ

. Label the

motor lead connected to the ohmmeter

A+

.

7. Repeat the procedure as outlined in step 6 for the

three leads labeled

B

(

BÊCENTER TAP

is the center

tap lead for Phase B of the motor).

8. Proceed to the

Terminal Connections

section below.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Summary of Contents for Compumotor ZETA6104

Page 45: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 49: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 53: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...

Page 63: ...Artisan Technology Group Quality Instrumentation Guaranteed 888 88 SOURCE www artisantg com...