8

TQ10 User Guide

Quick Test

The following installation procedure leads you through steps to permanently install your

drive. However, if you wish to familiarize yourself with the drive before you install it, you

can perform a bench top

quick test

. To do so, complete the following sections, in the order

given below:

Set configuration DIP switches (on top of drive). For bench top operation, set peak current at or

below the motor’s continuous current rating.

Set compensation DIP switches (on bottom of drive)

Connect a Controller (TQ10) or Indexer (TQ10SD)

• TQ10 Torque Drive – Connect Command Input signals

• TQ10SD Step & Direction Drive – Connect Step and Direction Inputs

Connect the Motor to the Drive

Connect AC Power

Test your system

During your permanent installation, complete the other sections in this chapter—drive and

motor mounting, connecting the load, and tuning.

Installation

The following procedures will lead you through the steps required to permanently install

your TQ10 Drive and motor.

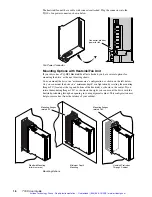

1. Set DIP Switches (Top of Drive)

Configure the TQ10 Drive’s DIP switches for your motor and application. Two 6-position

DIP switches—Switch 1 (SW1) and Switch 2 (SW2)—are located on top of the drive. The

table below summarizes their settings. A 3-position DIP switch—Switch 3 (SW3)—is

located on the bottom of the drive. See the section after this for instructions on setting SW3.

Default Settings

The factory default position is

off

for all switches. You must set these switches appropri-

ately for your application.

Peak Current

Set DIP switches SW1-#1 — SW1-#3 for the

peak current

that you want your drive to

produce. If you use a high performance motor (peak current rating greater than three times

the continuous current rating), such as Compumotor’s SM Series servo motors, see the

caution note below.

CAUTION

Peak current settings for initial drive tuning with SM and NeoMetric Motors:

Set peak current

at twice the motor’s continuous rated current, or less. Otherwise, motor damage due to

excessive heating may result from high peak currents and improper tuning values. See

Tuning

in this chapter for a procedure to iteratively raise peak current during tuning.

Time at Peak Current

Set DIP switches SW1-#4 — SW1-#6 to control the length of time the drive can produce

peak current, before it goes into current foldback.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com