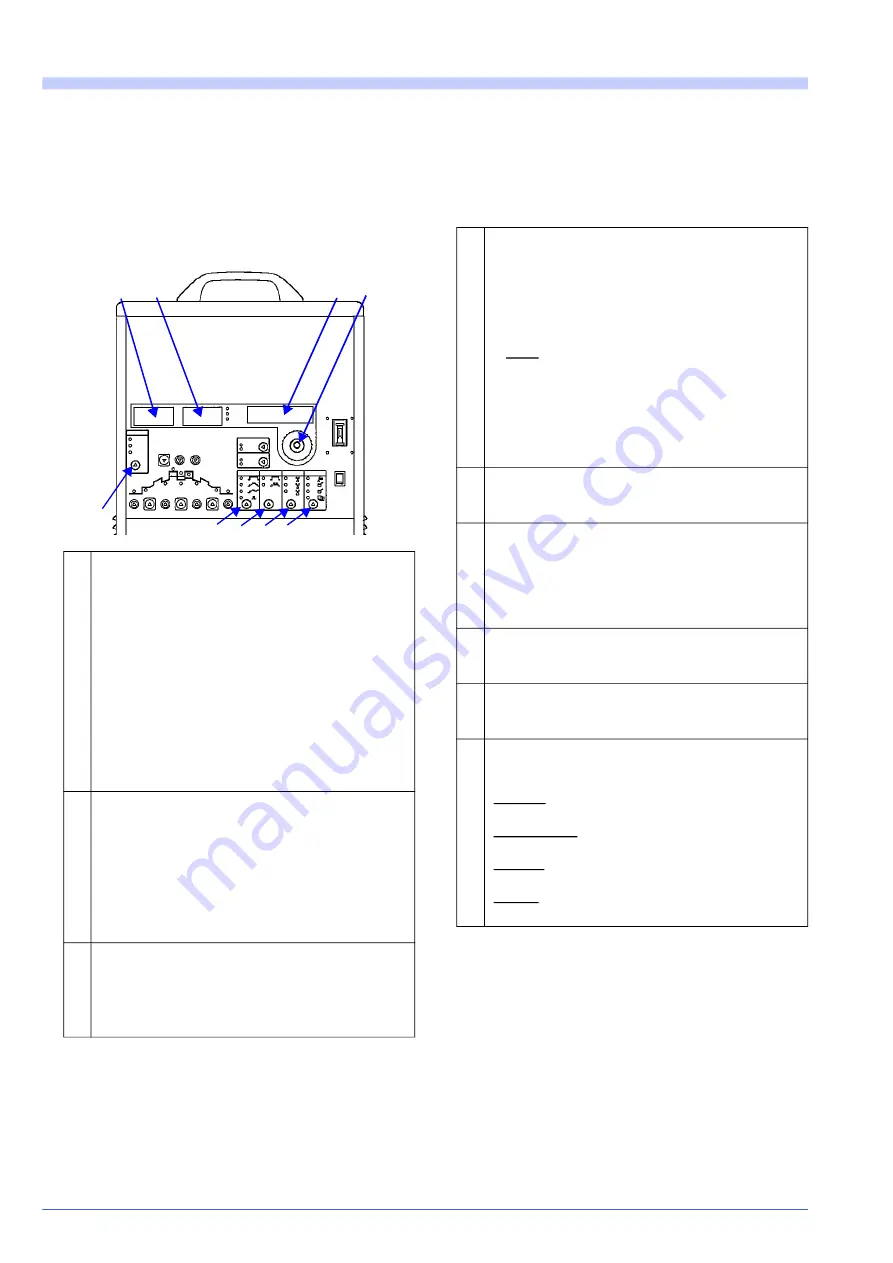

Names and Functions

OMCTT5639E09

18

4. Names and Functions

4.1 Front panel

4.1.1 Data display/setting section and welding conditions selecting section

For details of functions, see “Welding conditions” in this

chapter.”

*1

: In the case of a welding voltage, indicates the welding

voltage (between output terminals of this product) during

the welding operation rather than the set value.

*2

: See section “Operation” for how to display welding volt

-

age.

1

Digital ammeter

• Indicates welding current values during the weld

-

ing. (Displays an average current value mea

-

sured during the period of 0.4 second in

amperes.)

Due to a rounding error, a resulting value may

vary within the range of plus or minus 1A.

As this ammeter is designed to display an aver

-

age current value measured during the period of

0.4 second, it may not be able to follow the varia

-

tion of current quickly enough when the current

changes frequently during the pulse welding, etc.

• Indicates an “Err” (error) mark in case of a trou

-

ble.

2

Set-value display

• Indicates the set values

*

1

of current (A), time (S),

frequency (Hz), pulse width (%), AC balance (%),

DC ratio (%), welding voltage (V)

*

2

, etc.

• The unit display lamp changes according to the

type of indicated set values.

• Indicates an “Err” (error) number in case of a

trouble.

3

LCD display

• This is the information display area.

• Indicates condition-setting items in letters.

• Indicates error contents in letters in case of a

trouble.

1

2

3

4

5

7 8 9

6

4

Jog dial

• This is a dial to carry out the function of a potenti

-

ometer (setup of current and time).

For example, to set welding current to 125A, turn

the dial to the right (increase) or to the left

(decrease) until such a value is indicated (on the

set-value display).

Note: Turning the jog dial without discretion may

result in the change of a set value for the item

currently indicated on the LCD display.

• Use the press button function of the jog dial in the

following situation.

In the reproduction, storage or details mode (See

item 9 in the right column.)

5

“Weld conditions” selection button

Selects a required welding method (DC TIG, AC

TIG or MIX TIG).

6

“Crater control” selection button

Regarding the selected welding method, selects

the “absence, presence or repeat” of the crater

control, as well as the “spot” (arc spot welding).

The arc spot welding can be done only in the case

of “DC TIG” and “AC TIG” welding.

7

“Pulse” selection button

Regarding the selected welding method, selects

the absence or presence” of pulses.

8

“AC waveform” selection button

In case the AC welding method is selected, selects

an AC waveform (standard, hard or soft).

9

“Mote” selection button

Selects an operation “mode” of this product (weld

-

ing, reproduction, storage, or details).

Welding: Can be used to set welding conditions

and conduct a welding operation.

Reproduction: Can be used to reproduce stored

welding conditions.

Storage: Can be used to store the present welding

condition.

Details: Can be used to change the factory-set

mode of this product.

Summary of Contents for YC-300BP2YAF

Page 10: ...Rated Specifications OMCTT5639E09 10 2 2 1 Dimensions ...

Page 16: ...Installation OMCTT5639E09 16 Example of extension cable connection ...

Page 49: ...Parts list OMCTT5639E09 49 9 Parts list ...

Page 52: ...OMCTT5639E09 52 ...

Page 53: ...Circuit diagram OMCTT5639E09 53 10 Circuit diagram NF9 NF8 ...

Page 54: ...Circuit diagram OMCTT5639E09 54 10 1 Enlarged left half NF8 MCB ...

Page 55: ...Circuit diagram OMCTT5639E09 55 10 2 Enlarged right half NF9 ...

Page 62: ...OMCTT5639E09 62 ...

Page 63: ...OMCTT5639E09 63 ...