Installation

OMCTT5639E09

11

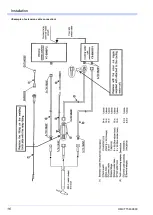

3. Installation

3.1 Installation siter

3.2 Power supply equipment

Note

• This Class A equipment is not intended for use in resi

-

dential locations where the electrical power is provided

by the public low-voltage supply system. There can be

potential difficulties in ensuring electromagnetic compati

-

bility in those locations, due to conducted as well as radi

-

ated radio-frequency disturbances.

• This equipment does not comply with IEC 61000-3-12. If

it is connected to a public low voltage system, it is the

responsibility of the installer or user of the equipment to

ensure, by consultation with the distribution network

operator, that the equipment may be connected.

CAUTION

This product is designed for indoor use only.

Do not install it in any places subject to rain or water spray.

CAUTION

Do not use this product in a vertical position

(i.e.: with its control panel side up).

Using it in the vertical position may reduce its cooling effect, and cause any

troubles like equipment burnout, etc. Therefore, make sure to use it in the

horizontal position (in the proper position).

(1) Locate indoors only in industrial environment area.

(2) Avoid exposure to the direct sun light or the rain or water

spray.

(3) Range of temperature of the ambient air:

(a) during welding:10 to 40 deg-C,

(b) after transport and storage:-20 to 55 deg-C

(4) Humid:

(a) up to 50% at 40deg-C,

(b) up to 90% at 20deg-C

(5) Altitude above sea level: up to 1000 m.

(6) Installing distance to maintain adequate airflow:

(a) 20 cm or more from any wall,

(b) 30 cm or more between power sources installed side-

by-side.

(7) Base of the welding power source inclined:max. 10deg.

(8) Avoid wind to the arc (provide windshields.)

(9) Free from abnormal amounts of dust, acid, corrosive

gases or substances etc. other than those generated by

the welding process (Especially, avoid where the metallic

substance may get into the power source.)

Note

When the product, which is installed on the floor, is too

low to operate, customers are required to prepare a

table to mount it. (And, in that case, provide such a table

with a flange, etc. so that the product does not slip down from

the table.)

20cm

30cm or more

CAUTION

Observe the following to prevent burnout, destruction of parts and

unstable arc.

Input voltage

200 VAC

Input current

32 A

Input protective devices

(Breaker, fuse etc.)

Type and capacity to be applied should conform to all national and

local codes.

Cable cross section area

for input cable and ground wire

Type and size of cables to be applied should conform to all national

and local codes.

Summary of Contents for YC-300BP2YAF

Page 10: ...Rated Specifications OMCTT5639E09 10 2 2 1 Dimensions ...

Page 16: ...Installation OMCTT5639E09 16 Example of extension cable connection ...

Page 49: ...Parts list OMCTT5639E09 49 9 Parts list ...

Page 52: ...OMCTT5639E09 52 ...

Page 53: ...Circuit diagram OMCTT5639E09 53 10 Circuit diagram NF9 NF8 ...

Page 54: ...Circuit diagram OMCTT5639E09 54 10 1 Enlarged left half NF8 MCB ...

Page 55: ...Circuit diagram OMCTT5639E09 55 10 2 Enlarged right half NF9 ...

Page 62: ...OMCTT5639E09 62 ...

Page 63: ...OMCTT5639E09 63 ...