36

4.7.2

Remove Trapped Air from the Retentate Line

Direct the retentate and permeate lines to feed tank.

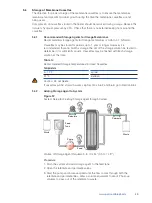

Figure 25

Setup for Buffer Conditioning — Recirculation

Procedure

1. Set up the system for recirculation.

2. Open the retentate and permeate valves.

3. Adjust the pump speed to give the recommended cross flow flux. Refer to Table 3.

4. Close the retentate valve until the feed pressure increases by 0.7 to 1 barg

(10 to 15 psig) or valve is completely closed, then open immediately.

Caution: Do not exceed a feed pressure of 3 barg (45 psig).

5. Repeat this step at least three times to remove air.

6.If necessary, adjust the pump flow rate to maintain a feed pressure of 1 to 2 barg

(15 to 30 psig) for UF membranes.

7. Recirculate fluid for 10 to 15 minutes if conditioning for pH and ionic stability at

ambient temperature. For equilibrating temperature between the hardware and

fluid stream, continue until the temperature has stabilized.

8. Check the torque on the cassette holder (not required for auto-torque (AT)

systems).

9. Remove the excess buffer from the feed vessel. Keep all piping, tubing, and

cassette assembly to and from the feed vessel flooded with buffer to prevent air

from entering the system.

It is necessary to determine the system hold-up volume in the feed/retentate flow

path. This volume will dilute the process fluid and must be considered when

calculating concentration factor. Refer to Section 3.3.

Retentate

Permeate

Feed

Tank

Feed

Pump

Rp

Pp

Fp