34

5. If the constant mass flow rate falls below the acceptance specification listed in

Table 12 (and is consistent with previous measurements), the membrane integrity

has passed. If the mass flow rate is above the recommended specification or

substantially above previous measurements, go to Section 4.6.5.

4.6.4

Troubleshooting System Integrity Failure

Procedure

1. If a manual-torque (MT) holder is used, check the torque. If an auto-torque (AT)

assembly is used, check to make sure the hydraulic pressure is at the correct

setting.

2. Check all sanitary clamp connections and fitting assemblies to assure they are

securely tightened.

3. Remove the cassettes and rinse with WFI water. Inspect the cassette gaskets and

the holder contact surfaces for imperfections. If the gaskets look worn or

deformed, install new gaskets. Reinstall the cassettes in the holder.

4. Repeat the System Integrity Test, Section 4.6.2.

4.6.5

Troubleshooting Membrane Integrity Failure

Procedure

1. If a manual-torque (MT) holder is used, check the torque. If an auto-torque (AT)

assembly is used, check to make sure the hydraulic pressure is set correctly.

2. Repeat the System Integrity Test.

3. Remove the cassettes and rinse with WFI. Inspect the cassette gaskets for

imperfections. If the gaskets look worn or deformed, install new gaskets. Reinstall

the cassettes in the holder.

4. Repeat the Membrane Cassette Integrity Test (Section 4.6.3). If the cassette still

fails an integrity test, contact your local Pall representative for assistance. If

multiple cassettes are installed and the air diffusion rate continues to exceed

specification limits, disassemble the stack of cassettes and test the integrity of

each cassette individually to determine if integrity failure is specific to a cassette.

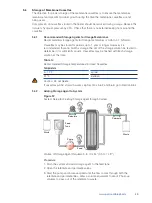

Figure 23

Typical Mass Air Flow Example Plotted for System and Membrane Integrity Test

4.6.6

Integrity Testing Systems with Multiple Cassettes

True integrity can only be validated on individual cassettes. Hence, testing should first

be done on each cassette separately. Then the individual cassettes can be installed

in the holder and tested as a unit. For a stack of cassettes, the air diffusion rate is

additive and should approximate the sum of the individual cassettes.

Air Dif

fusion Rate (cc/min)

Time (minutes)

0

External Test

Membrane Test

Diffusion Rate

Cassette Limit Specification

External Test

As the system fills with air to the

targeted test pressure, the air flow

rate will decrease to zero (base line).

If it does not reach zero, the system

has an external leak. Check all

fittings and valves.

Internal Membrane Test

When the permeate valve is open,

the air flow rate will rise. Then the

flow rate will decrease to a steady

state, which is the true air diffusion

(forward flow) rate.