44

Equation 7

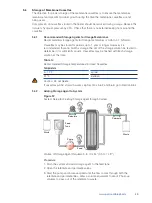

Water Permeability Calculation

5.4.3

Normalize the Water Permeability

Normalize the water permeability to a temperature of 20 °C using Equation 9:

Calculation for Membrane Recovery and the temperature correction factor (TCF

20 °C

)

in Table 11.

Equation 8

Calculation for Normalized Water Permeability

5.4.4

Determine the Membrane Recovery

Calculate the membrane recovery using Equation 9: Calculation for Membrane

Recovery.

Equation 9

Calculation for Membrane Recovery

5.4.5

Evaluate the Effectiveness of the Cleaning Regimen

For a new process, if membrane recovery is less than 100%, the cleaning regimen

should be repeated. This is to determine that the initial cleaning time at the selected

conditions was sufficient, and if not, to determine the appropriate number of cleaning

cycles or time required. If membrane recovery has improved after the second

cleaning cycle, a third cycle should be performed. When no additional improvement

in recovery is achieved, you know the last cycle time had reached maximum effect

for the conditions used. You may then use one cleaning cycle for the established

time or two or more cycles of shorter duration to equal the desired time. Several

cycles may be preferred, especially if cleaning is done at an elevated temperature

and the system cannot maintain temperature of the cleaning fluid.

Studies altering conditions, cycle time, temperature, or reagent concentration should

be performed to evaluate the most effective cleaning protocol for your process.

Note: Between uses, membrane cassettes are typically stored in a caustic solution

(0.05 to 0.1 N NaOH). During this time, remaining foulants on the membrane may be

degraded and removed when the membrane cassettes are flushed prior to the next

use. As a result of membrane relaxation and additional cleaning during storage, it is

not unusual for the membrane recovery, measured after storage, to increase relative

to the membrane recovery measured immediately after cleaning.

5.5

Post-Use Air Integrity Test (optional)

Post-use air integrity tests are not usually performed on TFF cassettes. There are no

requirements, as with sterilizing grade filters, that the cassette must pass a post-use integrity

test. Usually analysis of results, including performing a mass balance to establish if there is

product loss and where the loss might be, is sufficient to establish that the system is working

satisfactorily. If you wish to determine post-use integrity, follow the procedure given in

Section 4.6.

Water Permability =

Permeate Flux Rate (LMH)

TMP

NWP Recovery =

x 100%

NWP

after cleaning

NWP

initial

NWP

20 °C

=

X TCF

20 °C

Permeate Flux Rate (LMH)

TMP