5.2.2

Recirculate Cleaning Solution

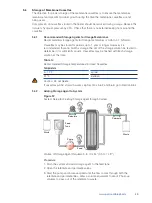

Figure 28

System Setup for Circulating Cleaning Solution

Return the retentate line to the feed tank.

1. Open the retentate valve and close the permeate valve completely. Adjust the

pump speed to give a retentate flow rate in the range of 1 to 1.5 times the

recommended process CFF rate in Table 3.

Caution: Do not exceed a feed pressure of 2.8 barg (40 psig).

2. Run 45 to 60 minutes for cleaning.

If the cleaning solution looks dirty after only a few minutes, stop cleaning and drain

the cleaning solution. Follow steps 5.1.1 and 5.1.2 to flush with water through the

retentate then the permeate. Add fresh cleaning solution to the feed tank and follow

the steps in Section 5.2.1.

5.3

Flush Cleaning Agent from Cassettes and Assembly

Flush the cassette and hardware assembly with either:

1. WFI at 25 to 45 °C, or

2. 0.2 µm filtered DI water at 25 to 45 °C

Volume Required:

40 L/m

2

(4 L/ft

2

) minimum

To establish required flushing volumes for a specific application, test the pH and/or conductivity

of water from the retentate to determine when acceptable conditions have been reached. If the

product will be in the permeate, test the pH and conductivity of the permeate.

www.pall.com/biopharm

39

Retentate

Permeate

Feed

Tank

Feed

Pump

Rp

Pp

Fp