32

Performing a System Integrity Test is recommended but not required. If the Membrane Cassette

Integrity Test passes, the integrity of the membranes and system is confirmed. However, if the

Membrane Cassette Integrity Test fails, then the System Integrity Test should be performed to

confirm that no external leaks contribute to the measured airflow.

The integrity test instrument should be placed at a level above the TFF system to prevent

gravity feed of liquid back into the instrument. (This is good manufacturing practice but not

absolutely necessary. The tubing arrangements of the Flowstar instrument protect the unit

against liquid ingress.)

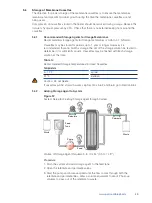

Figure 22

System Setup for Determining Air Integrity

4.6.1

Drain the System (Feed/Retentate Flow Path)

Note: The feed/retentate flow path must be drained of liquid before performing the

system or membrane cassette integrity test.

The procedure for draining the feed retentate flow path will depend on the system

configuration. The objective is to remove most of the liquid. It is not necessary to

completely remove all liquid.

Procedure

The liquid can be removed by any combination of the following steps:

1. Opening the drain and vent ports on the system to allow liquid to drain out.

2. Draining or disconnecting the feed tank and then using the feed pump (positive

displacement) to pump air into the system to displace liquid out through the

retentate line.

3. Using an integrity test air source to pressurize with air to force liquid out through

feed/retentate line. Liquid can also be forced out through the membrane and

permeate line.

Retentate

Integrity

Inlet Valve

Integrity

Outlet Valve

Air

Source

Permeate

Feed

Tank

Drain

Feed

Pump

Pp

Rp

Fp