5.2 PCM Conduit Installation

5.2.1 Pump Control/Pulser Conduit

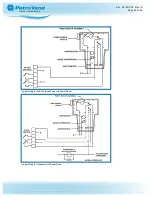

Install conduit runs from the PV100

®

to each pump junction box. These will contain the line voltage pump

control and low voltage pulser wires with the exceptions noted below.

Wires required are per fueling point. If conduit runs to a double-sided fuel pump, then the wire requirements

listed below must be multiplied by two (x2).

Wires (per fueling

point)

Wire Requirements

Pump Control

Six (6) wires (must meet pump manufacturer’s specification for pump being

controlled)

Pulser Wire

Two- or four-wire cable shielded – 600 V-Rated – Oil & Gas resistant, Wet Loca-

tions UL-style #2567

NOTE:

Pump Pulser Wires may share Pump Control Conduit when they meet the specified

requirements.

5.2.2 Pump Pulser Conduit

As an alternative to including the pulser wiring in the pump control conduit, a separate conduit for the pulser

wire can be run.

This conduit is dedicated to bringing the pump pulser wires from the pump junction box to the terminal

pedestal. Wires required are per fueling point. If conduit runs to a double-sided fuel pump, then wire

requirements listed below must be multiplied by two (x2).

Wires (per fueling

point)

Wire Requirements

Pulser Wire

Two- or four-wires. #18 AWG 600 V-Rated – Oil & Gas resistant, Wet Loca-

tions.

NOTE:

Please refer to the typical installation diagram (mechanical) for pump control conduit

wiring.

5.3 System Power Wiring

1. Pull three (3) #14-AWG wires (green [ground], black [line] and white [neutral]) from a dedicated circuit

breaker to supply power to the PV100

®

.

2. Connect power (black) and neutral (white) wires to the power connection terminal block marked “LINE”

(or “L”) and “NEUTRAL” (or “N”). Connect the green ground wire to the terminal labeled “GROUND” (or

“GND”).

Doc. No.: M1900 Rev.: 8

Page 23 of 65