Section 7 System Configuration

The configuration of the PV100

®

system is separated into two (2) parts:

Terminal Setup/Test Menu

and

Management Menu

.

l

The

Terminal Setup/Test Menu

(see

"" below

for further instructions) allows for the adjustment of

terminal system settings and peripheral devices.

l

The

Management Menu

(see

"Management Menu" on page 36

for further instructions) consists of

fuel site controller configuration options allowing you to manage card and pump processing conditions.

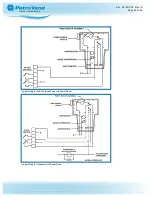

7.1 Terminal Setup/Test Menu

To access the

Terminal Setup/Test Menu

, open the door of the PV100

®

and flip DIP-switch bank #2,

switch #1 (located on the main board, as shown in

"Main Board DIP Switch Bank #2 and Reset Button" on

the next page

).

Next, hold the reset button for seven (7) seconds until the unit resets. The PV100

®

will restart automatically;

the

Terminal Setup/Test Menu

will come into view.

The Terminal Setup/Test Menu consists of the following configuration options:

1. Display

2. Keypad

3. Reader

4. Tones

5. System Network Number

6. Petro-Net Setup

7. Miscellaneous

8. Pump Control

9. Software Update

Doc. No.: M1900 Rev.: 8

Page 31 of 65