19

2.

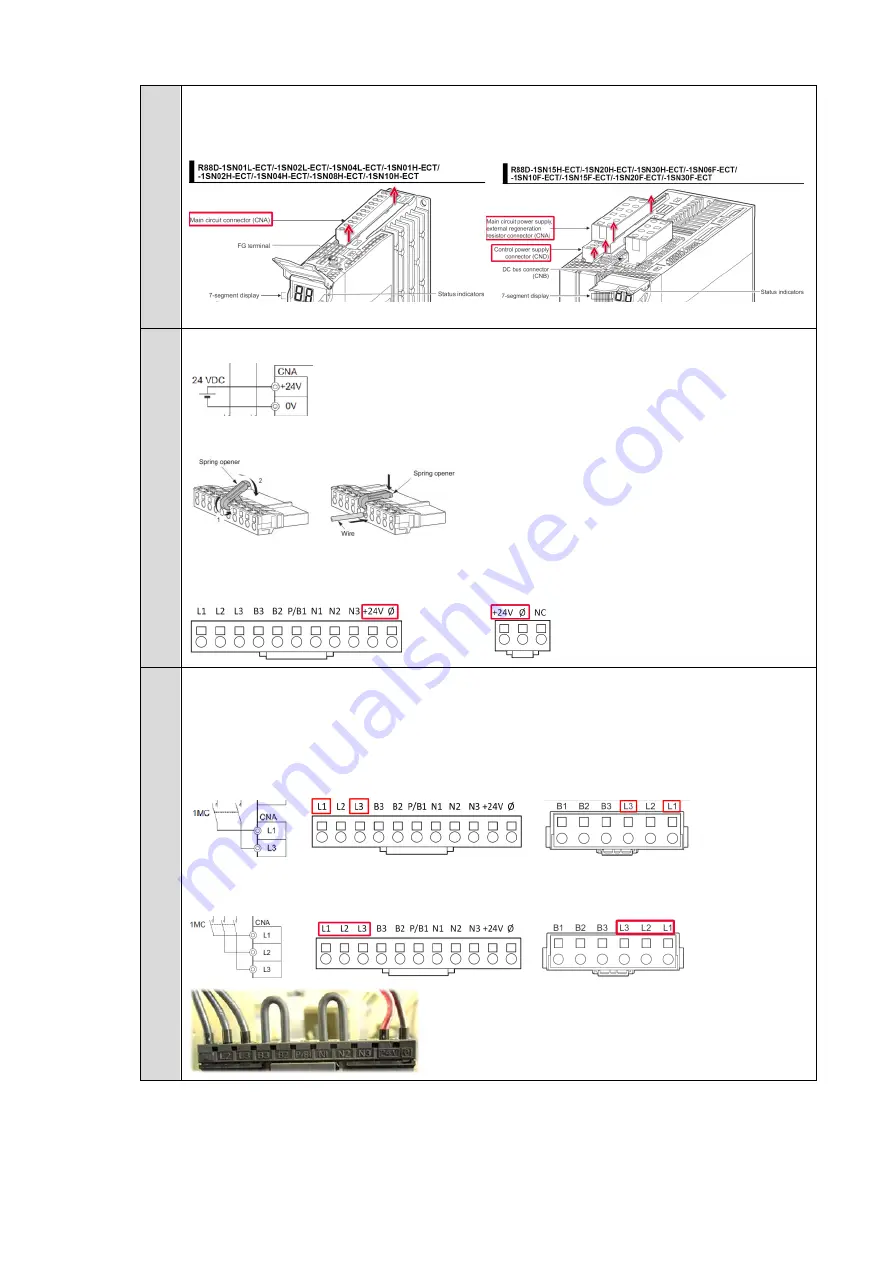

Remove power connector(s) (CNA) or (CNA)/(CND) from the drive depending on

the model:

100V/200V (up to 1kW) 200V (1.5kW-3kW) 400V (0.6kW-3kW)

3.

Please wire the 24V control power supply

(stripped wires or ferrules can be used)

Connect wires with the spring opener

Please refer to the corresponding connector depending on your drive and power supply:

CNA for 100V/200V (up to 1kW) CND for 200V (1.5kW-3kW) 400V (0.6kW-3kW)

4.

Please wire the AC power supply

Please refer to the corresponding connector depending on your drive and AC power

supply type

1-Phase

100V/200V (up to 1kW) 200V (1.5kW)

3-Phase

200V (up to 1kW) 200V (1.5kW-3kW) 400V (0.6kW-3kW)

Example:

(

CNA) for 100V/200V (up to 1kW)

Summary of Contents for R88D-1SNx-ECT Series

Page 17: ...17 2 Approach the drive from top to down 3 Tight the upper part 4 Tight the down part...

Page 38: ...38 6 Add the Emergency stop button 7 Add the Reset button 8 Edit I O Map variables...

Page 58: ...58 11 Results Wizard step 5 Save to EEPROM Finish...

Page 59: ...2016 0616 0616 I823 E1 01 Note Do not use this document to operate the Unit...