Construction Manual

www.oldschoolmodels.com

Page 5

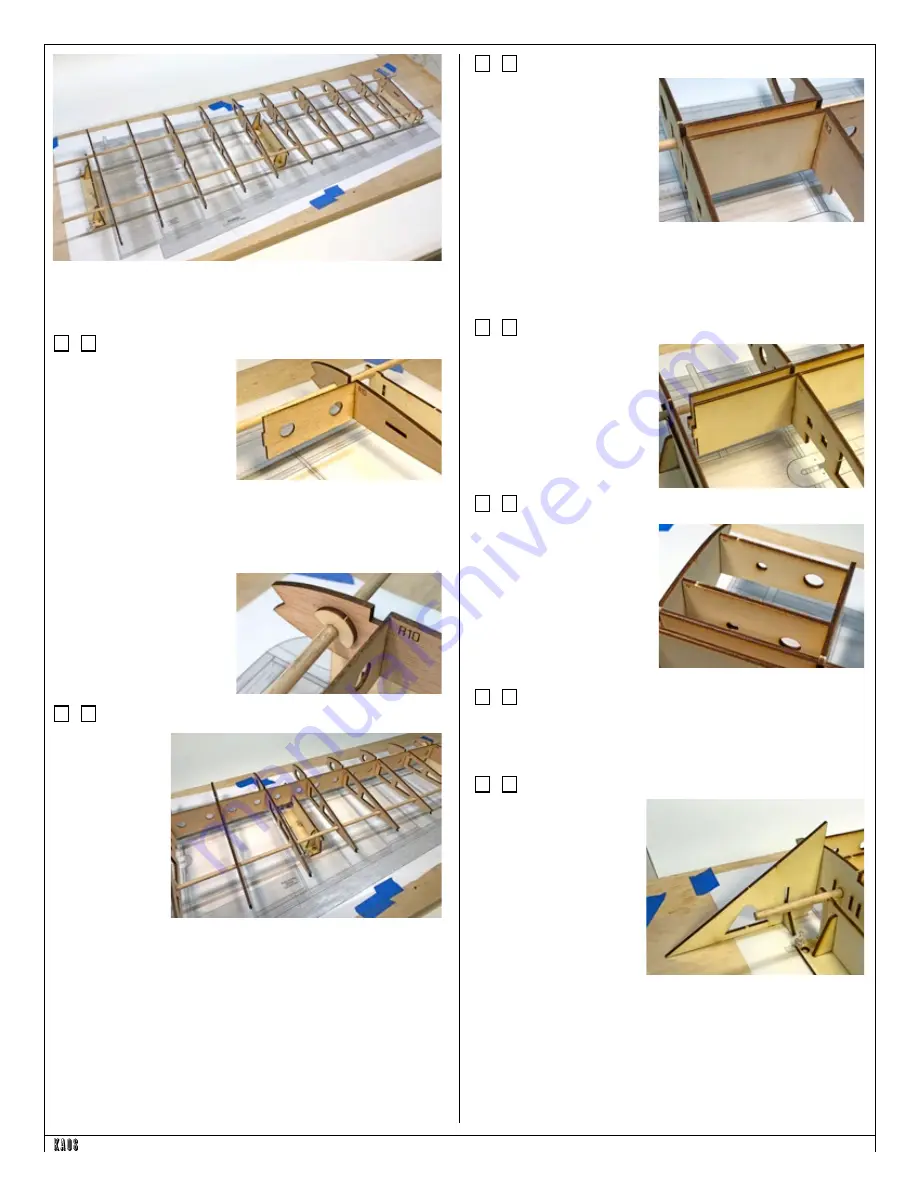

and the R6-R10 to the right side of the middle jig.

Now, snap the dowels on to the jig supports. Then carefully space

the ribs apart, to their proper locations as shown in the photo.

Step 7 - Wing Assembly (R10 & SW9)

Locate one SW9 from

BP11. Note that this has an

engraved circle, as do all of

the sheer web pieces. This

circle designates the top and

should also be positioned

towards the root rib (R1).

Glue SW9 to R10, making

sure SW9's tab is completely pushed into the corresponding slot in

R10. Also make sure the outer edge of SW9 contacts R10 along it's

entire height. Hold this away from the J2 jig until the glue cures.

Once cured, then push R10 against J2.

To help hold R10 (and any of

the other ribs) in place, there's

a bunch of J8's cut into LP1.

Wick thin C/A into any of

these you use first, then snap

them on to the dowel and use

them as a "stop".

Step 8 - Wing Assembly (SW3-SW8)

Locate one set of

SW3-SW8 sheer

webs from BP13.

Starting with R9,

you will attach

each of the

appropriate SW

pieces (as noted

on the plans)

and glue them

together as shown

here. You can

either do one at a time, or position everything in place, then glue

everything together at once.

Regardless of how you do it, make sure all of the SW circles are

positioned properly and their tabs are completely inserted into the

each rib's tab cutout before gluing. Also make sure that ribs are

aligned to the plan (remember to use the triangles we talked about

in step 1).

Even small errors here can multiply as you go along the wing and

causing larger and larger misalignments as you move further along

the wing.

Step 9 - Wing Assembly (SW2)

Locate two SW2s from LP1

and LP2. These are installed

the same way as the previous

SW pieces, just doing it twice.

You are paying attention

to where those etched SW

circles are, right?

Also - take care not to get any extra glue in the space between the

SW2 pieces (and the SW1s in the following steps). Any extra will

have to be filed away later on when fitting the dihedral brace, keep

this area as clean as possible.

Step 10 - Wing Assembly (SW1)

Locate two SW1s from LP2.

These are installed slightly

differently as they are only

glued to R2 at this time. You

can push them into R1 to help

position them, but don't glue

them to R1. Don't do it. Trust

me - it's better this way.

Step 11 - Wing Assembly (WH1 & WH2)

Locate one WH1 and one

WH2 from LP1. These have

circles as well, showing

upright and the edge that will

be against R1. Glue these in

position to R2, but again - not

to R1. Trust me - this will all

make sense in a couple more

steps.

Step 12 - Wing Assembly (WH3 & WH4)

Locate one WH3 and one WH4 from LP1. These also have circles

and you should know the drill by now. Pay attention to the

orientation, then glue them to R2, but not R1.

Step 13 - Wing Assembly (R1)

Back in step 1 I mentioned

the root rib triangle. Well,

now it's time to use it.

Take some time with this

step as you need everything

aligned, but also you

need R1 straight down

it's entire length.

Epoxy,

or slower curing glue is

recommended for this as

there are several pieces

being attached in succession.

Starting at the leading edge, start gluing and inserting the tabs

from the WH pieces the SWs and the remaining WH pieces into

R1. When they're all properly seated into R1, R1 should be at a 2°

angle. And you can verify this with the root triangle. Measure in

several places, all the way along it's length. And at the same time,