Oki Data CONFIDENTIAL

43967002TH Rev. 1

350 /

7. Troubleshooting

7.5.3.(3) All white page print (Refer to Fig. 7-2

C

)

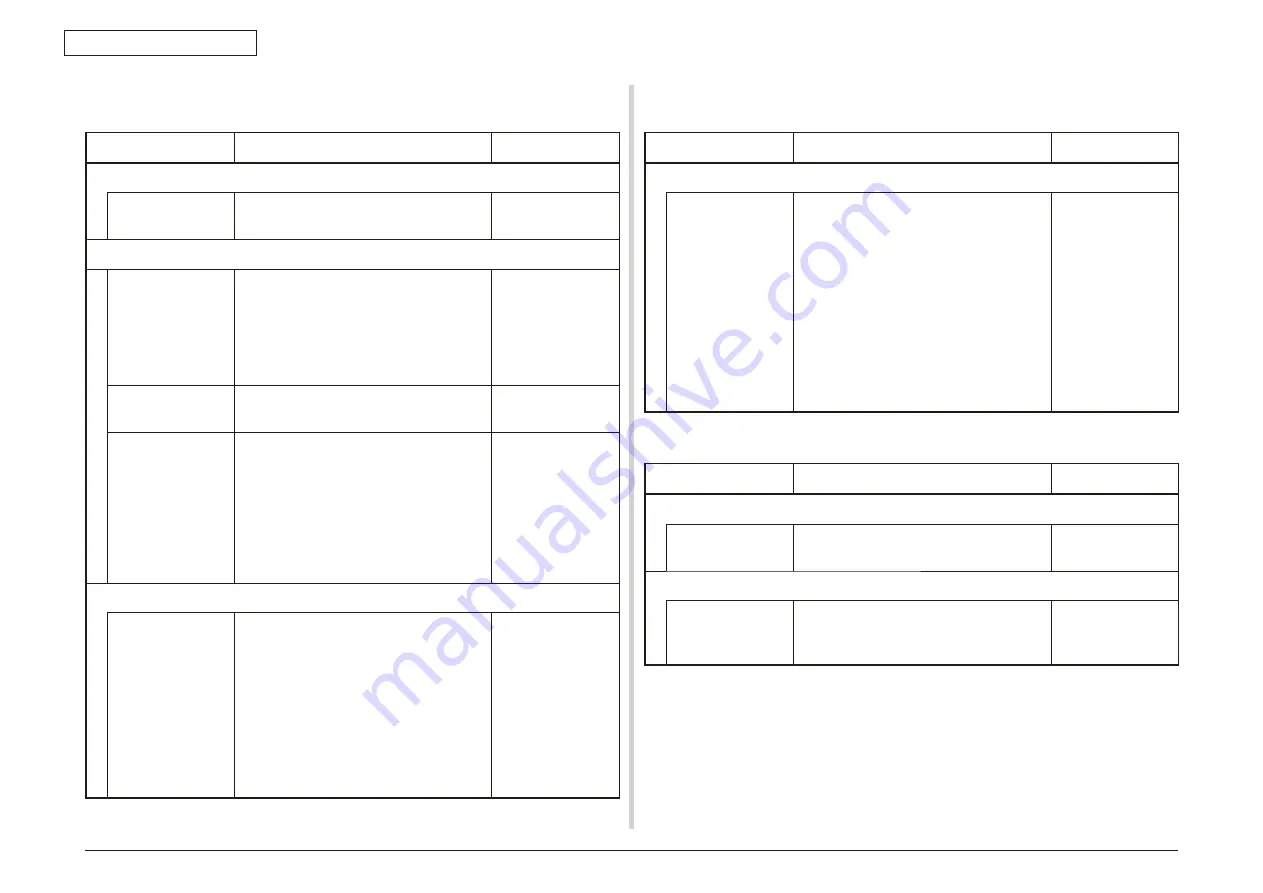

(3-1) All white page print on paper

Check item

Check work

Action to be taken at NG

(3-1-1) Toner condition

Residual amount of

toner

Check that sufficient amount toner remains

inside the toner cartridge.

Replace the toner

cartridge

(3-1-2) Exposure condition

LED head

Check that the LED head is located in the

good position where the LED head faces

against drum in the specified position.

Check if there exists any obstacle that

prevents irradiation on the irradiating

surface of LED.

LED head

installation condition

should be corrected.

LED head

connecting condition

Check that the LED head is normally

connected.

Replace the LED

head

Drum shaft

Check that the drum shaft is contacting

with the right and left side plates normally.

Replace the ID unit.

If any attempt of

using new ID unit

as a trial is going to

be made, be sure

to use the System

Maintenance Menu

FUSE KEEP MODE.

(3-1-3) High voltage terminal

ID unit terminal

Confirm that the ID unit high voltage

terminal keeps contacting with the high

voltage terminal by visual check.

(Refer to Fig. 7-3.)

ID unit replacement

or high voltage

terminal repair If

any attempt of using

new ID unit as a

trial is going to be

made, be sure to

use the System

Maintenance Menu

FUSE KEEP MODE.

7.5.3.(4) Vertical line is printed

(4-1) Thin vertical line (with color) (Refer to Fig. 7-2

D

)

Check item

Check work

Action to be taken at NG

(4-1-1) ID unit condition

ID unit filming

Has the MFP made printing without toner?

Replace the toner

cartridge with new

one. If it does not

correct the trouble,

replace the ID unit.

If any attempt of

using new ID unit

as a trial is going to

be made, be sure

to use the System

Maintenance Menu

FUSE KEEP MODE.

(4-2) Thin vertical line (with color)(Refer to Fig. 7-2

F

)

Check item

Check work

Action to be taken at NG

(4-2-1) LED head condition

LED head

Is there any foreign material attached to

the irradiating surface of the LED head?

Remove the foreign

material.

(4-2-2) Paper running condition

Paper running path

Check there is no blur in the paper running

path, that cause to scrape the non-fused

toner.

Remove the blur.