Oki Data CONFIDENTIAL

43163501TH Rev. 1

28 /

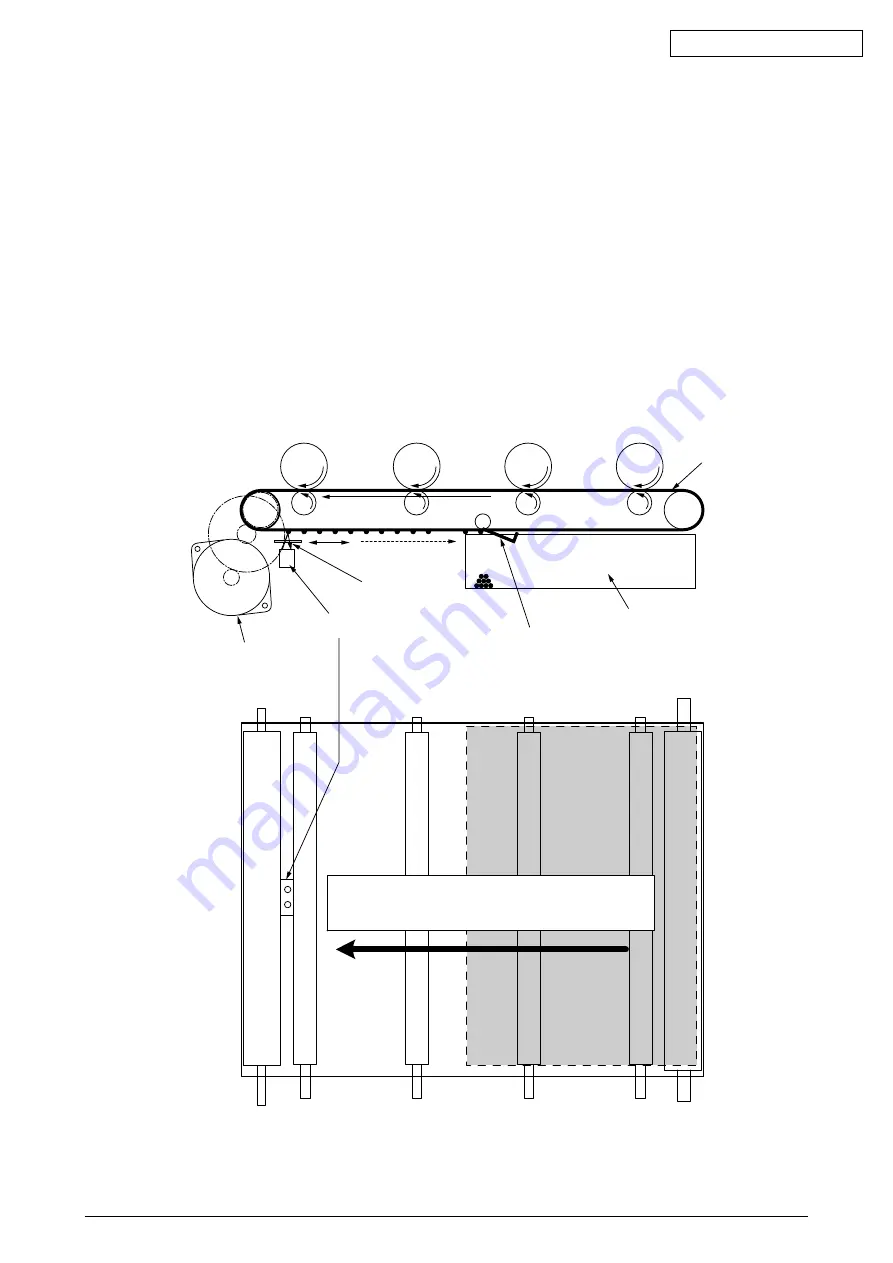

Density sensor

Density correction pattern

Belt waste toner box

Belt cleaning blade

Transport belt

Belt motor

Sensor shutter

Outline of Density Correction Method

Density correction is made by identifying the correction pattern printed on the belt using the sensor

installed in the sensor shutter under the belt unit.

Timing of automatic activation of density correction

• When the circumstance is significantly different from the previous work performance at the

time when the power is to be switched on.

• When at least one of the 4 ID count values is almost new at the time when the power is to

be switched on.

• When the ID count value is over 500 after the previous work performance.

Correction error can be caused by the amount of toner which generates the pattern, toner stain on

the sensor, malfunction of shutter opening and closing. However, as an error may not be displayed

on the operation panel, it may be necessary to confirm the error display by forcible execution of

the density correction test function (2. 4. 1. 5. 3) using the maintenance utility.

Error Confirmation Method and Countermeasure