Oki Data CONFIDENTIAL

43163501TH Rev. 1

97 /

5.4

Settings after Parts Replacement

The necessary adjustments after the parts exchange are explained as follows.

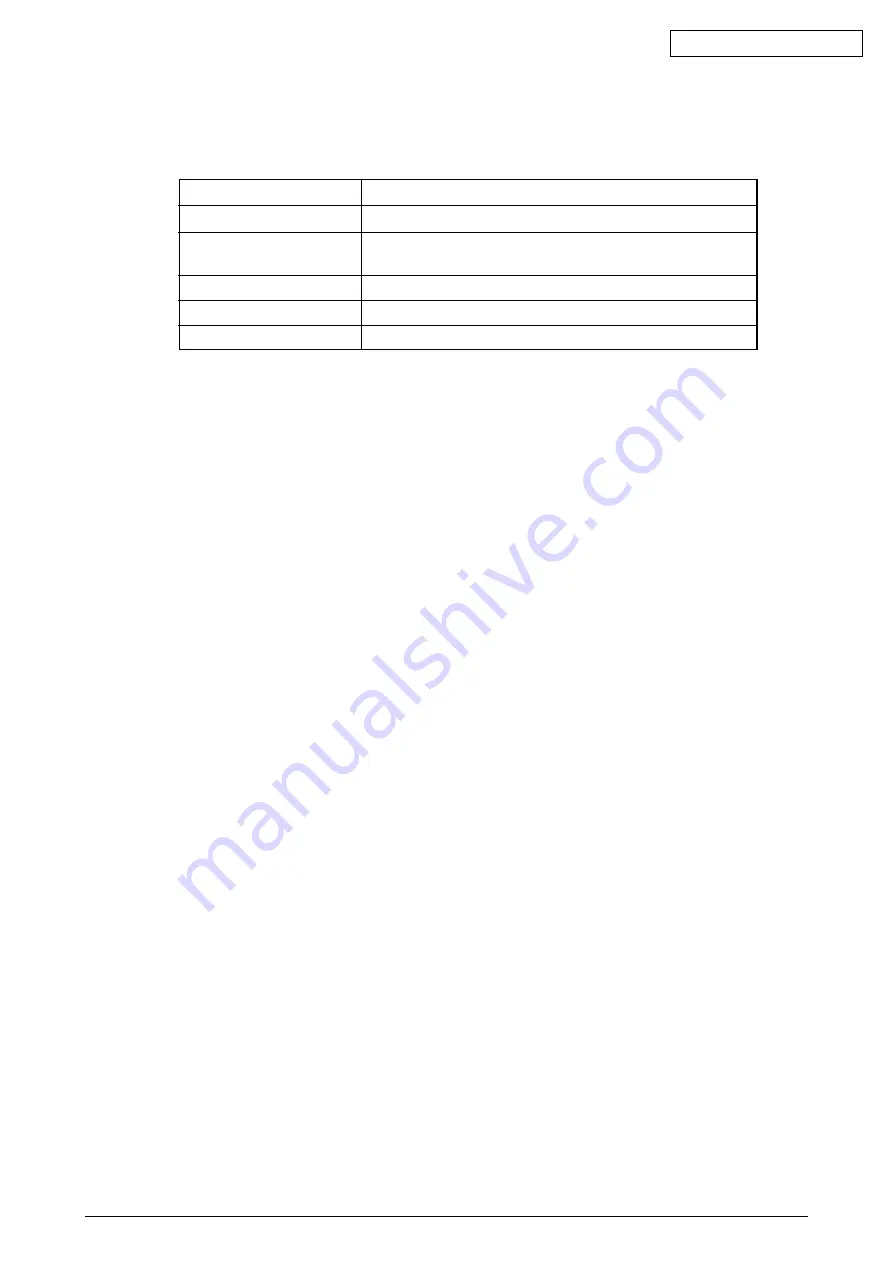

Replaced Part

Adjustment

LED Head

Not required.

Image Drum Cartridge

Not required.

(Any of Y, M, C and K)

Fuser Unit

Not required.

Belt Unit

Not required.

Main (BLA Board)

Copy the EEPROM information; utility is required

5.4.1 Notes when exchanging the main circuit board and EEPROM setting after the

exchange of BLA circuit board

1. When it is possible to access to the EEPROM of the circuit board to be removed

(When neither SERVICE CALL 40 [CU EEPROM Error] nor SERVICE CALL 105 [Engine

EEPROM Error] is displayed.)

(1) By using the PU board replacement function of the maintenance utility (maintenance utility

operation manual, Section 2.4.1.1.1, PU board replacement function and Section 2.4.1.1.3,

CU board replacement function), retrieve information about the CU EEPROM and the PU

EEPROM from the circuit board that is to be removed, and store the information temporarily

in the HDD of PC.

(2) By using the PU board replacement function of the maintenance utility (maintenance utility

operation manual, Section 2.4.1.1.1, PU board replacement function and Section 2.4.1.1.3,

CU board replacement function), copy the information about the CU EEPROM and the PU

EEPROM information stored in the HDD of PC by (1) to the EEPROM of a new circuit board

to be installed.

Note:

When using the maintenance utility to get the EEPROM information or writing the

information, please set the printer to “forcible ONLINE mode” following the procedures in

5.3.(1), then EEPROM can be accessed.

2. When it is impossible to access to the EEPROM of the circuit board to be removed

When SERVICE CALL 40 [CU EEPROM Error] or SERVICE CALL 105 [Engine EEPROM

Error] is displayed on the status monitor by handling the circuit board to be removed, or when

the EEPROM data cannot be read out, perform maintenance with the maintenance utility

according to the following procedure after replacing with a new circuit board.

(1) [When facing OEL]

(1-1) Set the PU serial number

(Maintenance utility operation manual, Section 2.4.1.2, PU circuit board setting)

SAP serial number can be applied to the device. The SAP serial number is displayed

in the highest rung of the serial number label. It is a 12-digit number including production

place (2 digits), production year (2 digits), sequence number (6 digits) and revision

number (2 digits).

• PU serial number is a 10-digit number which is basically the same as SAP serial number

except that it has no the 2-digit revision number.

• Set on the menu of [Section 2.4.1.1.2.1, PU serial number setting] of [Section 2.4.1.1.2

PU circuit board setting function].