- 40 -

UNDERWATER USE

1. Underwater use is acceptable but caution should be given as not to damage the unit

by striking it blindly below water level.

2. Caution should be given as not to allow water to get into the pump assembly when

changing a grease cartridge.

DO NOT

attempt to change a grease cartridge while

the unit is underwater.

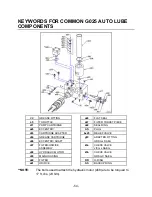

AUTO LUBE TROUBLESHOOTING

If the NPK Auto lube unit is not pumping grease correctly, the following steps may be

taken to diagnose and correct the problem.

PROBLEM CAUSE REMEDY

Eccentric shaft does not

rotate, pump does not

supply lubricant.

No pressure at P oil port of

Auto lube pump assembly.

Check the pressure setting

of the hydraulic circuit.

Filter/Diaphragm assembly

and throttle contaminated.

Clean the filter/diaphragm

and throttle assemblies.

Throttle is closed.

Turn the throttle adjustment

approximately 1-1/2 turns

counterclockwise. Start

hydraulic system, then re-

adjust the throttle to the

proper speed when the unit

is working again.

Hydraulic

motor

faulty.

Replace the hydraulic

motor.

Eccentric shaft rotates,

pump does not supply

lubricant.

Grease cartridge is empty. Replace

cartridge.

Air bubbles in the grease

cartridge.

Unscrew the grease

cartridge from the adapter.

Push the follower piston of

the cartridge by hand until

bubble free lubricant comes

out. Re-install the

cartridge.

DO NOT

overtighten!

Make sure flat seal is not

missing or damaged.

Replace the seals.

The pumping element is

faulty or worn out.

Replace the pumping

element.

Grease comes out of the

discharge opening of the

relief valve.

Grease system back

pressure is too high.

Check the hammer or the

grease line leading to the

hammer for blockage.

Relief valve is faulty.

Replace relief valve.

Grease comes out of the

lateral relief valve hole.

Pumping element is worn

out.

Replace the pumping

element.