- 39 -

BEFORE START-UP

PRIMING THE GREASE LINE

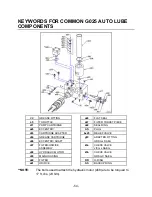

6. Pump grease through the pump to the

grease line (

29

) until a steady stream

of grease (

28

) is realized at the

opposite (hammer) end.

6a. It is also possible to purge the grease

line to the hammer by disconnecting it

at the hammer then pumping grease

through the grease fitting provided on

the grease pump assembly.

7. Re-attach the grease line (

29

) to the

hammer (KK).

8. Pump twenty more shots of grease

using the grease gun (t37) or power

greaser into the pump assembly (FZ).

This will prime the hammer cavity and

pre-lube the tool.

9. Look for grease coming out around the

tool (HH) at the tool bushing (see

arrow).

NOTE:

If the Auto Lube has run out of grease, the above procedure should be used to

purge all the air out of the line (

29

) before using the hammer. Failure to do this

will result in an intermittent supply of grease to the hammer.