- 45 -

GREASE CARTRIDGES

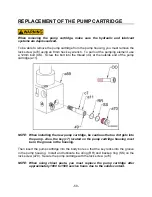

CHANGING THE GREASE CARTRIDGE (G025)

1. Remove the old grease cartridge.

2. Before installing the grease cartridge, make sure the flat seal (a65) is present and

not damaged. If the flat seal is missing or damaged, see

“CHANGING THE FLAT

SEAL”

and

“CHANGING THE CARTRIDGE ADAPTER”

.

3. Inspect the lubricant passage.

4. Apply a light coat of grease to the o-rings (RR) located in the cartridge adapter

(a53).

5. To accelerate priming, first remove the cap from the cartridge opening. Then, using

the cartridge follower piston (a66), press the grease (

28

) out 3/16” – 3/8” (

5 – 10 mm

).

6. Next, insert the cartridge into the cartridge adapter by pressing it slightly, then

threading it in by hand.

DO NOT OVERTIGHTEN!

NOTES:

1. In the case of a new unit being used, fill the lubricant passage through the grease

fitting (

30

) provided on the front side of the pump assembly.

2. If the cartridge piston is at the bottom of the cartridge, the latter must be replaced.

The follower piston can be easily checked through the inspection window (

155

) on

the front side of the pump assembly (G025 only).

When replacing the cartridge, make sure that no contamination enters the intake

area of the pump assembly. This can result in pump damage.