Troubleshooting

6-11

E

1996 Nordson Corporation

All rights reserved

107 041A

Issued 1/96

Manual 12-28

Problem

Possible Cause

Corrective Action

1. Conveyor rail does not

change position

(contd.)

Open cable 2355

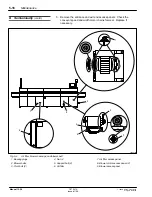

Slide a piece of paper through minimum

and maximum limit-optical switch slots

on limit switch board. While sliding

paper, verify that dual-motor controller

card LED’s L3 and L4 turn on.

If LED’s do not turn on, use an

ohmmeter to check cable 2355:

230PL–1 pin C5 to 237PL–1 pin 4

230PL–1 pin C6 to 237PL–1 pin 3

230PL–1 pin C1 to 237PL–1 pin 2

230PL–1 pin C4 to 237PL–1 pin 1

Repair as necessary.

Bad dual-motor controller card

NOTE: If limit flag activates limit-switch

board’s optical switch before rail reaches

its inner limit, PRD WIDTH actual

column should read calibrating. If it

does not, replace dual-motor controller

card.

If movable rail is not at inner limit, turn

off oven. After a few seconds, turn on

oven. Enter

RAISE COVER SCREEN

menu. Verify that PRD WIDTH actual

column displays “???”. If actual column

contains a number, replace the

dual-motor controller card.

If menu message reads recalibrate,

enter PRD WIDTH setpoint of 50.8. Use

a voltmeter to measure voltage between

pins (A19,C19) gnd and (A20, C20) on

dual-motor controller card. If 40 VDC is

not present, replace dual-motor

controller card.

NOTE: Dual-motor controller card LED

L3 is on while the limit-switch board

minimum LED is off.

Conveyor Width Control

Problems

(contd)

Summary of Contents for 107 041A

Page 1: ...Select Cure 100 Inch IR Oven Part 107 041A NORDSON CORPORATION D AMHERST OHIO D USA ...

Page 9: ...E 1995 Nordson Corporation All rights reserved Issued 11 95 12 28s1 Section 1 Safety ...

Page 10: ...Safety 1 0 E 1995 Nordson Corporation All rights reserved Issued 11 95 12 28s1 ...

Page 148: ...Parts 7 0 E 1996 Nordson Corporation All rights reserved 107 041A Issued 1 96 Manual 12 28 ...