Maintenance

5-10

E

1996 Nordson Corporation

All rights reserved

107 041A

Issued 1/96

Manual 12-28

WARNING: Risk of electrical shock. Remove power to the

oven. Failure to observe this warning may result in personal

injury, death, or equipment damage.

CAUTION: Adjust chain temperature at room temperature only.

Failure to observe this caution will result in conveyor motor and

gear box damage.

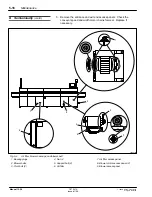

Adjust the conveyor tension and width after the initial 400 hours of oven

operation and, as required, thereafter.

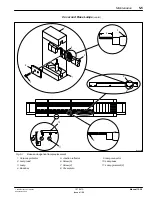

Checking Chain Tension

Chain buckling and kinking on the large sprocket or slack on the middle

sprocket at the oven exit indicates tension problems.

To adjust chain tension, perform the following steps:

NOTE: Make all tension adjustments to the non-spring load idler tension

block located at the opposite end of the conveyor rail.

1. Turn off the oven at the main disconnect. Let the oven cool off.

2.

Remove the sprocket guards (6) and rail covers (3)

from the entrance and exit ends of the conveyor rails.

3. Using two open end wrenches, adjust the idler block assembly (2) for

3 mm (0.125 in.) of upward travel.

NOTE: If tension adjustment problems occur, remove or add links.

4. Make sure that all conveyor rail sprockets remain in alignment.

5. Repeat steps 3 and 4 for the remaining rail.

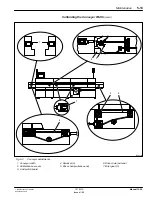

Setting the Conveyors Minimum Width Limit

Perform the following steps to align the movable rail:

1. Remove the hinged side access panels.

2. Make sure that the rail uprights are vertical and straight.

3. Make sure all bearings are free-turning.

Conveyor Adjustments

Summary of Contents for 107 041A

Page 1: ...Select Cure 100 Inch IR Oven Part 107 041A NORDSON CORPORATION D AMHERST OHIO D USA ...

Page 9: ...E 1995 Nordson Corporation All rights reserved Issued 11 95 12 28s1 Section 1 Safety ...

Page 10: ...Safety 1 0 E 1995 Nordson Corporation All rights reserved Issued 11 95 12 28s1 ...

Page 148: ...Parts 7 0 E 1996 Nordson Corporation All rights reserved 107 041A Issued 1 96 Manual 12 28 ...