INSTALLING AND REMOVING THE OPTIONAL UNIT

5-4

9

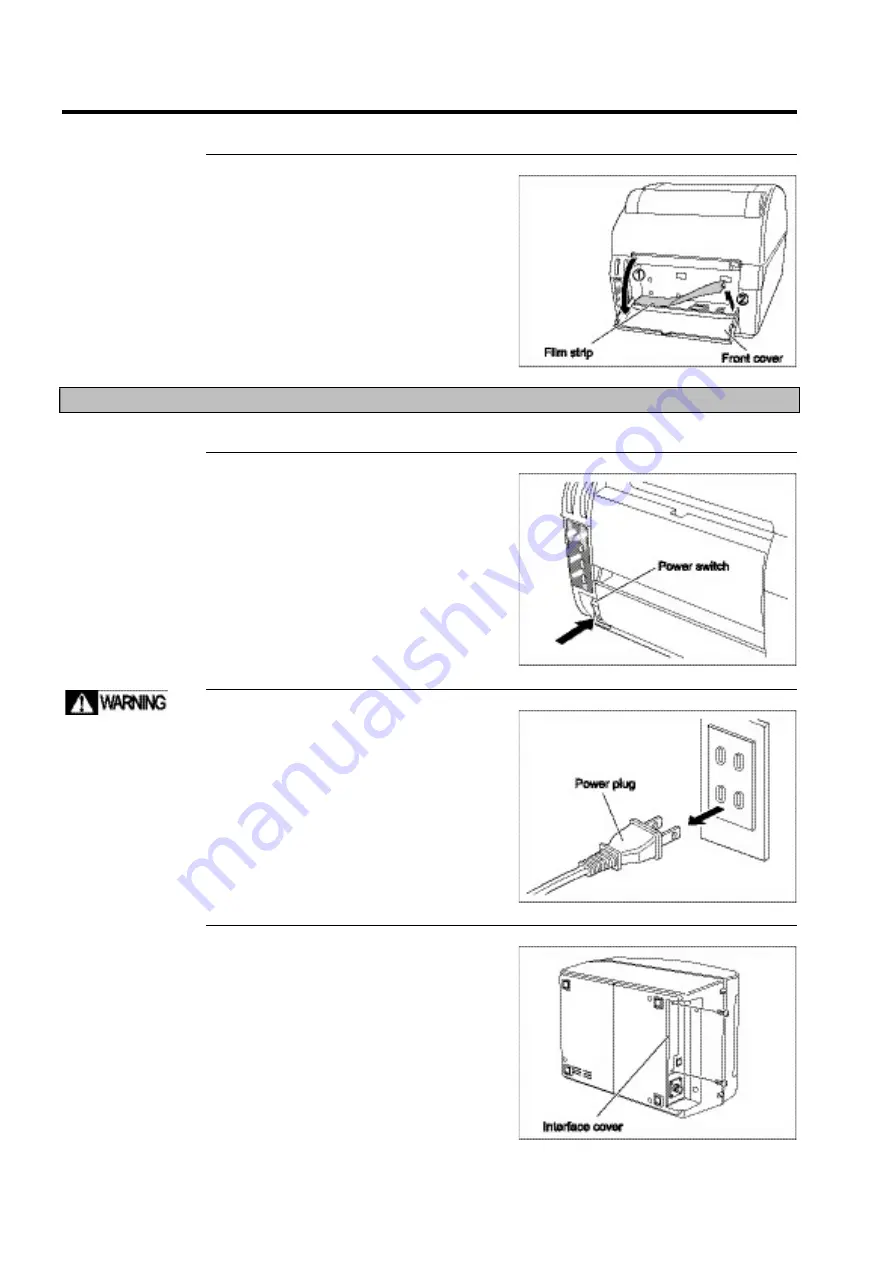

Open the front cover and set the

DIP switches.

For information on the DIP switch settings,

refer to step 6 in “3.1 Operation Checks

During Installation” on page 3-2.

<Removing components>

Remove components by following the steps

for installation in reverse order from step 8.

5.1.2

Installing and removing the RS-232C board

This section explains installation and removal of a RS-232C board.

1

Press the power switch to turn

off the printer.

The POWER light goes off and the power

shuts off.

2

Unplug the printer from the

power outlet.

3

Turn the printer on its side and

remove the interface cover by

removing the two screws.

Be sure to unplug the

printer from the

power outlet. Not

doing so may result

in personal injury or

an equipment

malfunction.

Summary of Contents for DURA PRINTER SL

Page 1: ...DURAPRINTER SRs T H E R M A L P R I N T E R I N S T R U C T I O N M A N U A L ...

Page 13: ...PREFACE XII ...

Page 16: ...BEFORE OPERATION 1 3 Rear view Operating panel ...

Page 67: ...MAINTENANCE 4 24 ...

Page 83: ...INSTALLING AND REMOVING THE OPTIONAL UNIT 5 16 ...

Page 89: ...DURA PRINTER SL SETTING TOOL 6 6 ...

Page 97: ...APPENDIX 7 8 ...

Page 98: ...P N A2136E ...