521-OM0108.88

Copyright

2009 Nalco Company

4-22

Technical Help

(630) 305-CHEM

3D TRASAR

5500 - Installation & Operation Manual

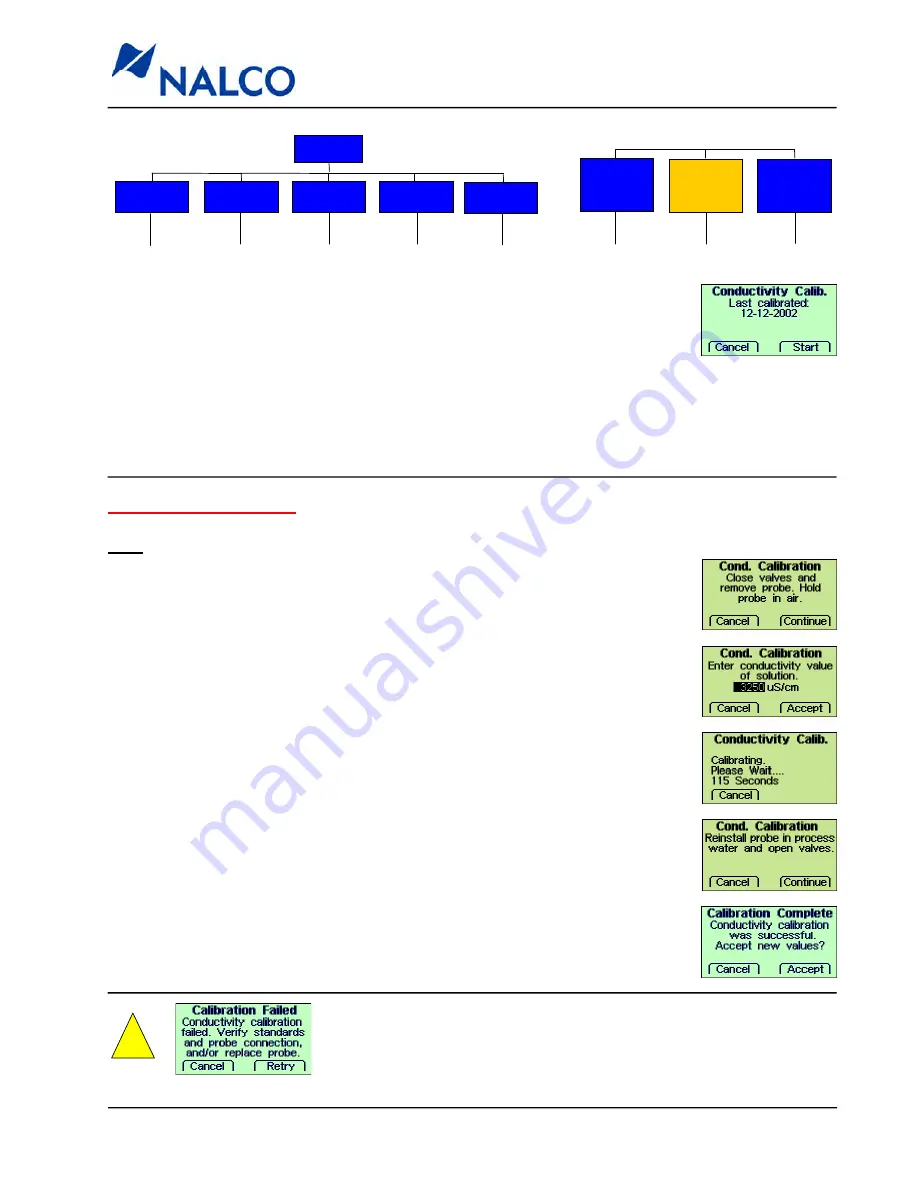

4.10.6 Conductivity Calibration Screens

Select

Conductivity

and follow the screen directions to perform calibration:

A

2-point calibration

is best utilized when installing a new probe or if a major

error has developed due to excessive fouling or probe degradation.

A

1-point calibration

utilizes the system water as the calibration point. It is best

used to fine-tune your calibration to compensate for minor drifting. Leave the

probe in the process water. The 1-point calibration range is +/-10% of the

second point value of the previous 2-point calibration.

Control

Settings

Alarm

Settings

Preferences

System

Info

Network

Information

Manual

Relay

Actions

Menu

Alarms

For a 2-point calibration

Tips

√

Conduct the 2-point conductivity calibration after completing other cali-

brations (pH, ORP, etc.).

√

A calibrated conductivity meter with correct temperature coefficient for

the process water is required.

√

Measure the water sample and obtain an accurate conductivity value.

√

Follow the instructions on the screen.

√

Standard solution for the probe calibration is not required. If using a

standard solution for the calibration, choose a solution close to the

value of the process water conductivity value.

STEP 1

- Select a

2-point

calibration.

STEP 2

- Close the sample inlet, lower sensor outlet, and 3-way valves.

STEP 3

- Remove the conductivity probe from the Tee and dry it.

STEP 4

- Hold the probe in the air. Press

Continue

.

STEP 5

- Wait two minutes

STEP 6

- Reinstall the probe into the Tee and open all valves to let the

process water flow. Press

Continue

.

STEP 7

- Press

Edit

and use the keypad to enter the accurate value of

the process water. Press

Accept

.

STEP 8

- Wait six minutes.

Accept

the new value if successful, or Retry

if failed.

!

If probe calibration failed, clean the probe, check wiring con-

nections, or handheld conductivity meter for accuracy and

recalibrate.