3D TRASAR

5500 - Installation & Operation Manual

521-OM0108.88

Copyright

2009 Nalco Company

9-9

Technical Help

(630) 305-CHEM

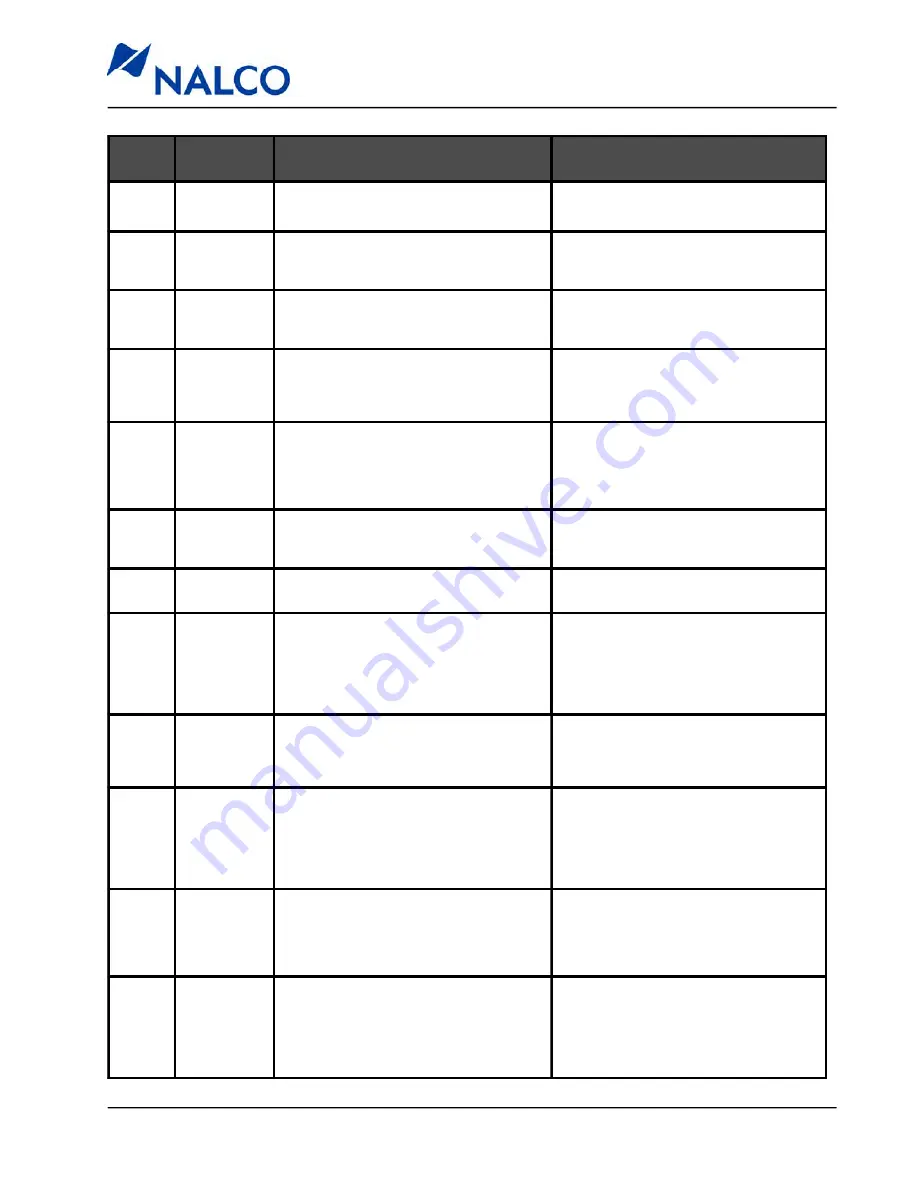

Alarm

Type

Indication

Probable Cause

Corrective Action

Ball Valve

Error

Pellet Feeder ball

valve not rotati ng

1) Ball valve separated from motor shaft.

1) Contact Help Desk at 630-305-CHEM for

assistance.

Ball Valve

Current

High

Pellet Feeder ball

valve drawing too

much current

1) The Pellet Feeder ball valv e is jammed.

2) The Pellet Feeder valve seats h ave been over

tightened.

1) Disassemble ball valve, clear jam.

2) Adjust valve seats (see Pellet Feeder

Maintenance Section 6.8).

Pellet

Rotor

Current

High

Pellet Feeder

rotor drawing too

much current

1) The Pellet Feeder rotor is jammed.

1) Remove pellets from hopper and clear jam. Rotor

shield may be worn and require replacement (see

Pellet Feeder Maintenance Section 6.8).

Bio-Index

High

Microbio activity

is not under

control

1) Oxidizing Biocide tank empty or pump lost pri me.

2) Increased biocide demand detected, and controller

is responding appropriately.

3) Biocide program requirements have changed.

1) Check and refill tank or reprime pump.

2) No action required. If this persists for 3 days,

contact Help Desk at 630-305-CHEM for assistan ce.

3) Reassess biocide program with your local Nalco

Representative.

Biocide

Pump

Rate High

Biocide feed rate

is too high to

control accurately

1) Biocide pump rep/stroke are set too high , or pump

is too large for system.

1) Adjust feed rate downward or replace with a lower

capacity pump. After downward adjustment, reset 3D

Bio-Control by changing the Oxi dizing Biocide Control

Method first to None (reboot controler) then back to

3D Bio-Control (reboot controller). Otherwise,

persistant Bio Index High Alarms may occur.

Biocide

Pump

Rate Low

Biocide feed rate

is too low to

control microbio

activity effectively

1) Biocide pump/stroke are set too low, or pump is

too small for system.

1) Adjust feed rate upward or replace with a h igher

capacity pump.

Bio-

product

High

Bioproduct level

exceeds alarm

threshold

1) Biocide feed unable to meet microbio demand.

1) Manually feed Oxi dizing Biocide into system until

alarm clears.

Bio-

product

High

Failsafe

Bioproduct level

exceeds alarm

threshold for an

extended period,

and oxidizing

biocide enters

failsafe mode

1) Same causes as Bioproduct High.

1) Same. Alarm must be cleared at the di splay.

Bio-

product

Low

Bioproduct level

below alarm

threshold

1) Bio-reporter feed is insufficient.

2) Excessive Oxidizing Biocide degrading bioreporter.

Source of Oxidizing Biocide may be makeup, manual

feed, process or other leak, or oversi zed biocide

pump.

1) Check bio-reporter pump or pellet feeder, or verify

adequate bio-reporter inventory.

Bio-

product

Low

Failsafe

Bioproduct level

below alarm

threshold for an

extended period,

and oxidizing

biocide enters

failsafe mode

1) Same causes as Bioproduct Low.

Same. Alarm must be cleared at th e display.

Bio-

reporter

High

Bio-reporter level

exceeds alarm

threshold

1) Too many Quick Dose pouches were added at

start-up.

2) Bio-reporter was overfed by manual control or

malfunctioning pump.

3) If in conjunction with Bioproduct High, biocide feed

unable to meet microbi o demand.

1) Wait for level to come down. Additi onal bio-

reporter will not be fed.

2) Wait for level to come down. Additi onal bio-

reporter will not be fed.

3) Manually feed Oxi dizing Biocide into system until

alarm clears.

Bio-

reporter

High

Failsafe

Bio-reporter level

exceeds alarm

threshold for an

extended period,

and oxidizing

biocide enters

failsafe mode.

1) Same causes as Bioreporter High.

1) Same. Alarm must be cleared at the di splay.