-

23

-

Maintenance and Inspection of Brake

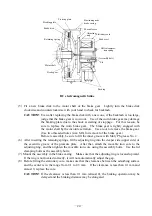

Electromagnetic Hoisting Brake

The hoisting brake is located on the end face of the hoisting motor. The brake stops and holds a

load.

For the 5t

、

10t types, the brake gear is engaged to the motor shaft.

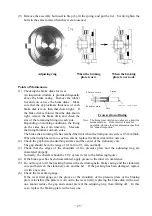

The 5t

、

10t types are provided with an automatic adjusting device that keeps the gap constant

between the iron cores even if the brake disk is worn out. The gap therefore does not need to be

adjusted. If the brake does not work effectively and the load travels a considerably long distance

after applying the brake, judge that the brake disk is worn out to the limit. In this case, replace

the brake disk with a new one.

[Procedure for disassembling and re-assembling the brake and replacing the brake disks for

the 5t ,10t types]

(1) Remove the lid screwed on the end face of the stationary core, and remove the helical

compression spring. Evenly loosen the bolts. Remove the spring, taking care not to

damage the packing.

CAUTION!

: When loosening the bolts of the lid, you may notice that the lid is sticking to

the casing due to the sticky packing. In this case, apply a shock to the lid

before completely removing the bolts. In this way, you can prevent the lid

from springing out.

(2) Using the bolts removed from the lid, temporarily tighten the movable iron core and the

pressure plate.

CAUTION!

: If the movable iron core and the pressure plate are not temporarily tightened,

the adjusting ring may fall off, or two retaining springs (small springs that

ensure easy falling down of the adjusting ring) may be missing.

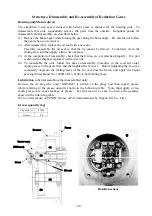

(3) Remove the stationary core, taking care not to damage the packing. The brake coil is in the

stationary core.

CAUTION!

: This packing prevents “entering of water into the brake casing”, and also

prevents “electromagnetic leakage from the electromagnet”. If the packing is

broken, replace the packing with a new one. If the brake is reassembled

without a packing, the suction gap will be narrowed by 0.8 mm (= packing

thickness “t”). In this case, the brake may be locked up, and the motor may be

seized. If the electromagnetic leakage occurs, the responsibility of the brake

may be deteriorated.

(4) Remove the temporarily tightened movable iron core, adjusting ring, and pressure plate to

remove the brake disk and the braking plate.

CAUTION!

: When replacing the brake disk, clean the inside of the break box. Be sure to

remove abrasion particles from the back of the braking plate, contact face of the

brake box, and the guides (lugs) of the brake disk and braking plate.

Summary of Contents for UM 10t

Page 51: ... 47 Structural Drawing of Hoist Main Body 5t 10t PA00531 ...

Page 52: ... 48 Structural Drawing of Electric Traversing Unit Monorail Type 10t P288922 ...

Page 53: ... 49 Structural Drawing of Electric Traversing Unit Double rail type 5t PA00483 ...

Page 54: ... 50 Structural Drawing of Traversing Mortor Double rail type 10t P276926 ...

Page 55: ... 51 Structural Drawing of Hook Block 5t PG49975 ...

Page 56: ... 52 Structural Drawing of Hook Block 10t PG49976 ...