-

28

-

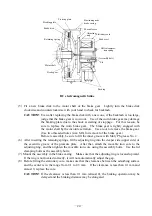

Structure, Disassembly and Re-assembly of Reduction Gears

Hoisting unit(Main reducer)

The simplified 2-step speed reducer with helical gears is adopted for the hoisting unit. To

disassemble this unit, sequentially remove the parts from the outside. Important points for

disassembly and reassembly are described below:

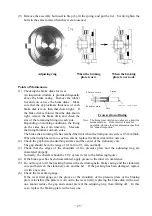

(1) Remove the helical gear while turning the gear along the helix angle. Be careful not to flaw

the gear when you remove it.

(2) After disassembly, replace the oil seal with a new one.

Carefully reassemble the oil seal so that the lip cannot be flawed. Completely clean the

sliding area, and then apply a thin coat of grease.

(3) At the completion of reassembly, check that the C-ring, etc. are attached properly. If a part

is distorted or chipped, replace it with a new one.

(4) To reassemble the unit, follow the above disassembly procedure in the reversed order.

Apply grease to the gears first, and then tighten the G-cover. Before tightening the G-cover,

completely degrease the mating faces of the G-cover and the frame, and apply the liquid

packing (Three Bond No. 1208D or No. 1104) to both mating faces.

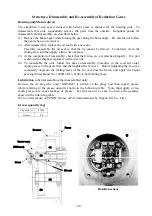

Lubrication

(when reassembling the disassembled unit):

Remove the oil plug (the word “GREASE” is written on the plug), and then supply grease

while referring to the grease quantity shown in the following table. Note that supply of too

much grease may cause leakage of grease. For this reason, be sure to observe the quantity

shown in the following table.

We recommend use of EPNOC Grease AP-O (manufactured by Nippon Oil Co., Ltd.).

Grease quantity (kg)

Capacity (t)

5t,10t

Grease

2.0

Rotation sensor

2G

3G

4G

1G

Frame

G-cover

Oil seal

RRS board

Cover

Sensor case

Summary of Contents for UM 10t

Page 51: ... 47 Structural Drawing of Hoist Main Body 5t 10t PA00531 ...

Page 52: ... 48 Structural Drawing of Electric Traversing Unit Monorail Type 10t P288922 ...

Page 53: ... 49 Structural Drawing of Electric Traversing Unit Double rail type 5t PA00483 ...

Page 54: ... 50 Structural Drawing of Traversing Mortor Double rail type 10t P276926 ...

Page 55: ... 51 Structural Drawing of Hook Block 5t PG49975 ...

Page 56: ... 52 Structural Drawing of Hook Block 10t PG49976 ...