- 41 -

Problem Cause

Remedy

12. The motor overheats

(1) Inching operation is performed too frequently.

(1) Apply a special design.

(2) Electromagnetic brake not released.

(2) See Item 13.

(3) Operating time long

(3) Adopt the same remedies as

Item 10, or do not use the

motor too frequently.

(4) Overload.

(4) Reduce the load.

13 Pressing a pushbutton

rattles the contactor.

(1) Extreme voltage drop

(1) Refer to Item 10.

14. The relay functions, but

the electromagnetic

brake is not released.

The electromagnet will

not attract.

(1) Too large voltage drop, or too low supply

voltage

(1) See Items 10 and 11.

(2) Too large core gap

(2) Replace the brake disk.

(3) No gap, or gap adjusted too large.

(3) Re-adjust.

(4) Movable parts catch on something.

(4) Repair.

(5) Brake circuit cable broken, or screws

loosened.

(5) Check, and repair.

(6) Brake circuit diode (DC) defective

(6) Replace the diode assembly.

(7) Coil burnt out.

(7) See Item 15.

(8) Too large center clearance

(8) Correct.

15. The electromagnetic

brake coil has been

burnt out.

(1) High frequency of uses

(1) Correct the operation method,

and replace the coil.

16. The electromagnetic

brake does not work

effectively.

(1) Too large core gap

(1) Replace the brake disk.

(2) The relay does not function properly.

(2) Replace the relay.

(3) The electromagnetic contactor cannot properly

cut off the power.

(3) Check the internal wiring.

(4) Adhesion of oil to the brake disk

(4) Degrease the brake disk, or

replace the brake disk.

(5) The immediate cut-off contactor does not

operate properly. (Direct current)

17. The traversing brake is

too effective or

ineffective.

(1) Brake adjustment failure

(1) Adjust the brake properly

with the adjusting bolt.

18. Rotation with the

traversing brake

applied.

(1) Brake coil wire breakage, or mis-connection

Replace, or repair.

(2) Diode defective, or mis-connection

(3) Too small or large gap

19. The traversing motor

does not have enough

rotation power, or will

not function.

(1) Brake coil wire breakage, or mis-connection

Replace, or repair.

(2) Diode defective, or mis-connection

(3) Too small or large gap

20. The gears make too

loud noise.

(1) Gears and bearings worn out

(1) Replace.

21. Traversing wheels spin. (1) The traversing wheel on the driving side is

lifted due to the inclined I-beam.

(1) Install the hoist in the reverse

direction.

(2) Paint, oil, or dust is on the transfer surface of

the I-beam.

(2) Clean, or, if necessary, grind.

22. The trolley wheels are

easily disconnected.

(1) The trolley wire has not been stretched as

specified.

(2) The trolley pole has been installed in the

reverse direction.

(3) Wheels not on the same level

Improve.

Summary of Contents for UM 10t

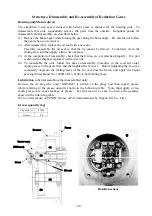

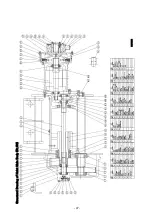

Page 51: ... 47 Structural Drawing of Hoist Main Body 5t 10t PA00531 ...

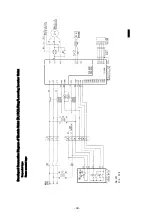

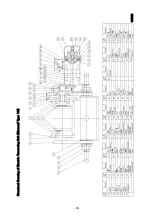

Page 52: ... 48 Structural Drawing of Electric Traversing Unit Monorail Type 10t P288922 ...

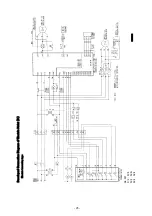

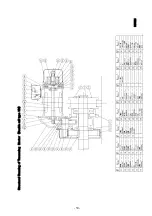

Page 53: ... 49 Structural Drawing of Electric Traversing Unit Double rail type 5t PA00483 ...

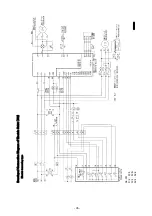

Page 54: ... 50 Structural Drawing of Traversing Mortor Double rail type 10t P276926 ...

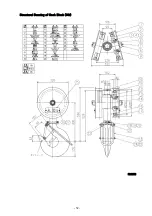

Page 55: ... 51 Structural Drawing of Hook Block 5t PG49975 ...

Page 56: ... 52 Structural Drawing of Hook Block 10t PG49976 ...