- 37 -

・

Lubrication

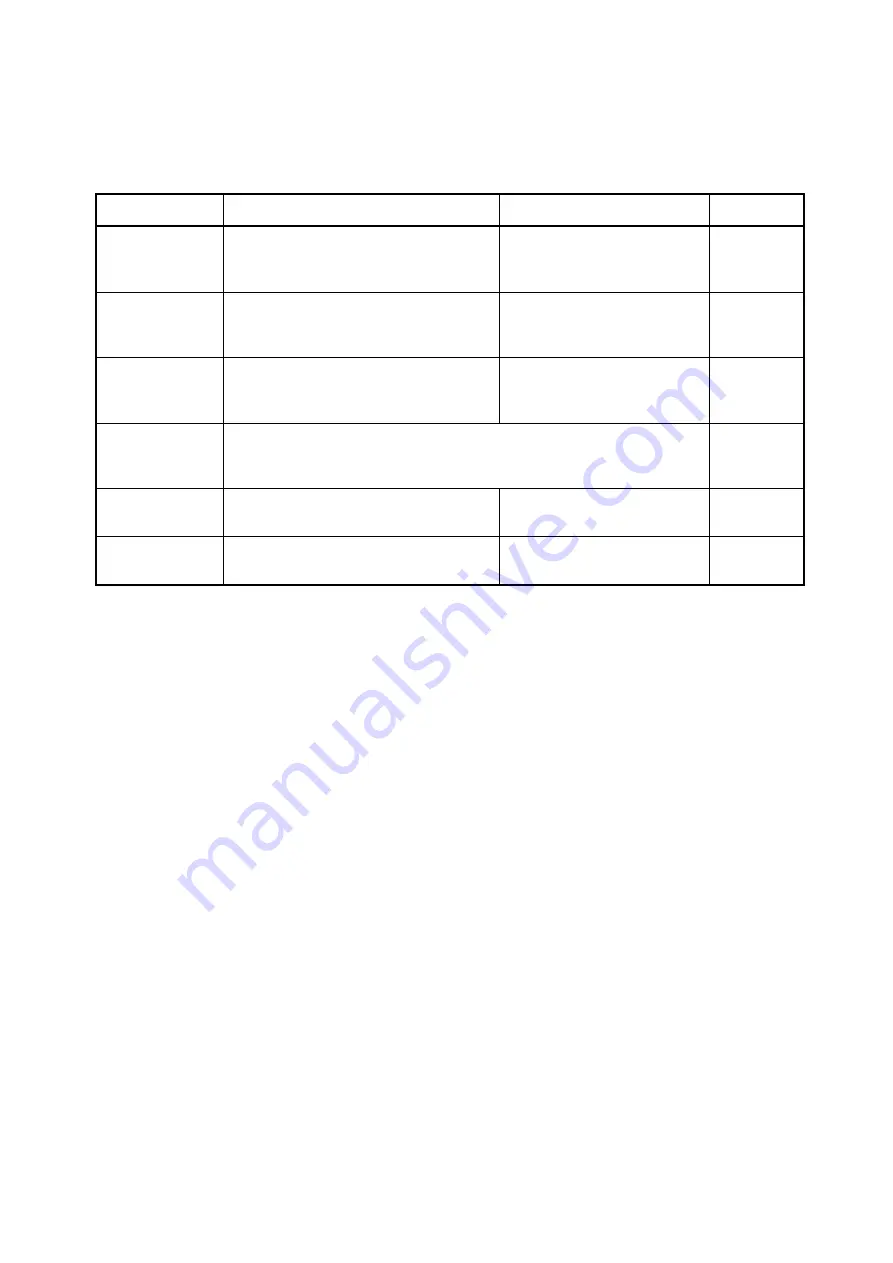

Please execute an inspection as well as oiling in accordance with the following table. However,

the table will provide typical example data relative to a standard hoist, and therefore, the standard

of lubrication oiling can be substantially varied in response to usage frequency as well as usage

condition.

Lubricated part

Kind of lubricant

Method

Frequency

Hoisting gear case

Refer to the “speed reducer” described in

“Structure, Disassembly, and Reassembly

of Reduction Gears”.

Lubrication and replacement

Once per

year

Traverse traveling

gear box

Refer to the “traversing unit” described in

“Structure, Disassembly, and Reassembly

of Reduction Gears”.

To be applied to the gear

surface.

Once per

year

Each individual

ball bearing

section

Lithium series grease No. 2 or equivalent,

Multi-purpose grease.

Refill lubrication oil up to

around 1/3 of the entire space.

At overhaul

Both sides sealed

up ball bearing

The external part only shall be cleaned, while, it is not required to overhaul

the internal parts. If any abnormality is observed, it shall be replaced.

(High-temperature resistant bearings are used for the motor.)

At overhaul

Sliding revolution

part

Grease equivalent to No. 2 and No. 3

To be applied.

At overhaul

Spline serration

part

Moly PS grease No. 2

(SUMIKO LUBRICANT)

To be applied.

Once per

year

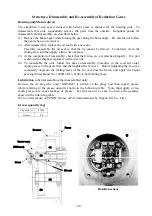

Summary of Contents for UM 10t

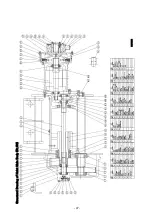

Page 51: ... 47 Structural Drawing of Hoist Main Body 5t 10t PA00531 ...

Page 52: ... 48 Structural Drawing of Electric Traversing Unit Monorail Type 10t P288922 ...

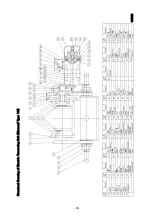

Page 53: ... 49 Structural Drawing of Electric Traversing Unit Double rail type 5t PA00483 ...

Page 54: ... 50 Structural Drawing of Traversing Mortor Double rail type 10t P276926 ...

Page 55: ... 51 Structural Drawing of Hook Block 5t PG49975 ...

Page 56: ... 52 Structural Drawing of Hook Block 10t PG49976 ...