UM_NX-W_00_05_19_ML

EN

MITSUBISHI ELECTRIC HYDRONICS & IT COOLING SYSTEM S.p.A.

29

Translation of the original instructions

•

the machine must be transported according to the regulations in force taking into account the characteristics of the fluids in the machine and the description of these

on the safety data sheet

•

inappropriate transport can cause damage to the machine and even leaking of the cooling fluid. Before start-up, the machine must be checked for leaks and repaired

accordingly

•

the accidental discharge of refrigerant in a closed area can cause a lack of oxygen and, therefore, the risk of asphyxiation: install the machinery in a well ventilated

environment according to EN 378-3 and the local regulations in force

•

the installation must comply with the requirements of EN 378-3 and the local regulations in force; in the case of installations indoors, good ventilation must be

guaranteed and refrigerant detectors must be fitted when necessary.

•

unless arranged otherwise with MEHITS, the machine be installed in environments where there is no risk of explosion (SAFE AREA)

•

the structure of the unit is not designed to withstand the stresses (accelerations) caused by an earthquake

•

before initial start-up, and in any case before maintenance, check that any shut-off taps of the cooling circuit are fully open

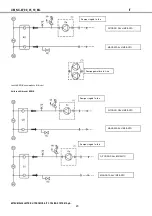

Residual risks

Mandatory personal protective equipment

Residual mechanical risks

Residual electrical risks

Other residual risks

Residual risks for maintenance

3.5

General precautions

•

during storage and transport, keep the machine within the following temperature ranges in relation to the refrigerant inside (wider ranges are possible and must be

requested when ordering):

R134a / R1234ze / R1234yf / R513A

R410A / R404A / R407C / R454B / R32

T min (°C)

-10

-10

T max (°C)

55

45

Tab.1

•

prevent the fluids in contact with the heat exchangers from exceeding the limits prescribed in the technical bulletin or from freezing, even when the unit is turned off

•

when there is a hydraulic circuit, do not use fluids other than water or mixtures of water and ethylene/propylene glycol at the maximum concentration allowed for the

components installed

•

the machine must only be put to the use for which it was designed; any other uses can be dangerous and will render the guarantee null and void

•

carrying out maintenance on the product can be dangerous: in the event of a fault or malfunctioning, please contact an authorised assistance centre

•

the installation must guarantee that the temperature of the fluid entering the unit remains stable and within the range indicated; be careful, therefore, when adjusting

any external heat exchanging and control equipment (dry coolers, cooling towers, zone valves, etc.), sizing the mass of fluid circulating the plant (particularly when

parts of the plant are excluded) and installing systems for circulating the required amount of fluid, in order to keep the temperature of the machine within the allowable

ranges (e.g. during start-up).

•

the packaging used to protect the machine must always be kept out of the reach of children as it represents a hazard

•

in units with compressors in parallel, do not disable the individual compressors for long periods of time; always respect the demand limit function

•

If necessary, use the emergency circuit breaker to disconnect the unit from the power supply

3.6

Environmental information

The cooling circuit contains fluorinated greenhouse gas covered by the Kyoto Protocol. The units may only be serviced and disposed of by qualified technicians.

The fluorinated greenhouse gases contained in the cooling circuit must not be disposed of in the atmosphere.

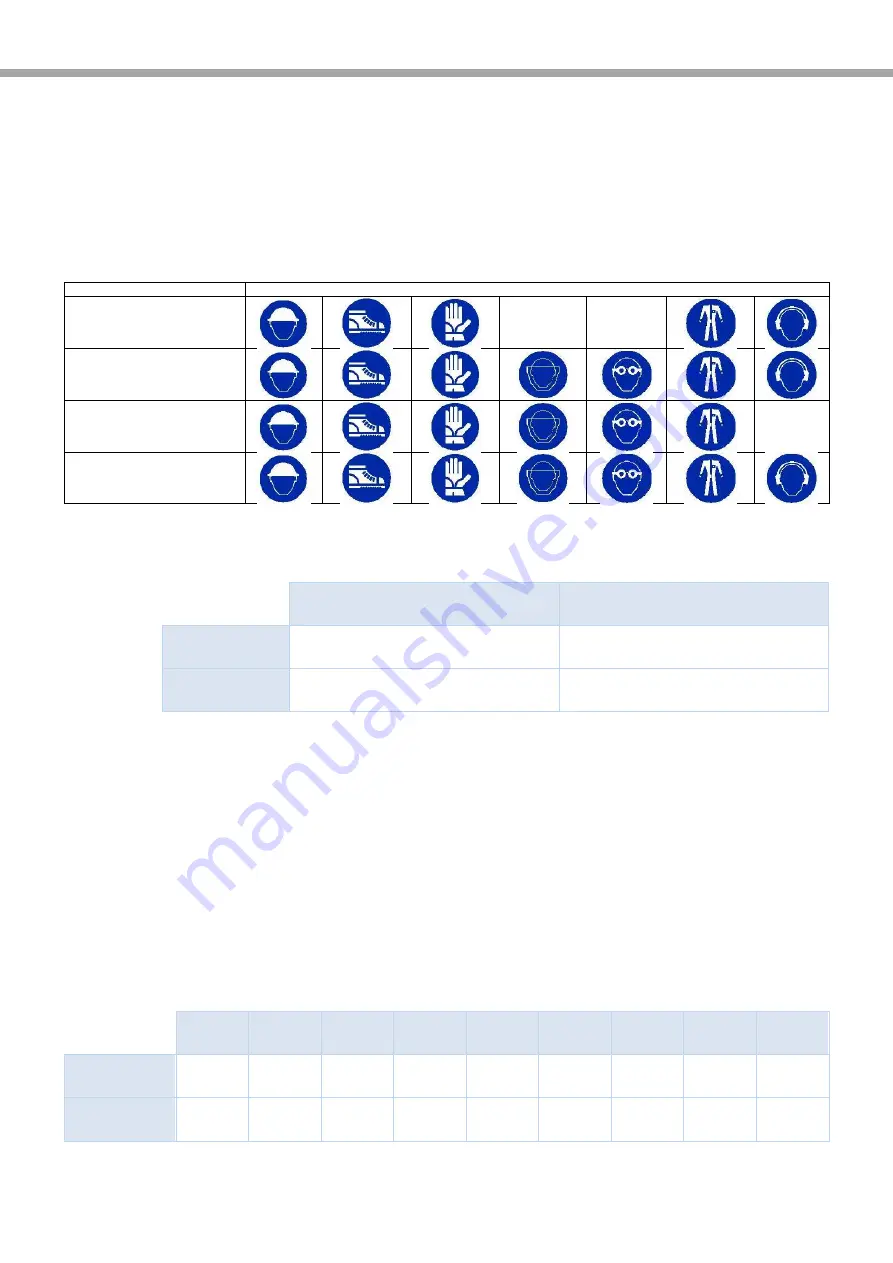

R134a

R1234ze

R1234yf

R513A

R410A

R404A

R407C

R454B

R32

GWP

100yr

ITH (IPCC

AR4)

1430

7

4

631

2088

3922

1774

466

675

GWP

100yr

ITH (IPCC

AR5)

1300

<1

<1

573

1920

3940

1620

467

677

Tab.2