USE ONLY YOUR

FINGERS TO DEPRESS

THE KEYS.

NEVER USE SHARP

OBJECTS.

WHEN USED PROPERLY

THIS KEYPAD WILL

WITHSTAND HEAVY

INDUSTRIAL USE.

DAMAGE MAY OCCUR IF

KEYS ARE DEPRESSED

BY A SCREWDRIVER,

PEN, ETC.

Î

FIGURE 14

(MSIN0201BE)

Î

All Machines

WARNING

DO

NOT

TAMPER

WITH

INDIVIDUAL

CONNECTIONS

ON

THIS

"WIRE-WRAPPED" CONTROLLER, OTHERWISE THE WIRE WRAPS MAY BE

LOOSENED WHEREUPON ELECTRICAL CONTINUITY COULD BECOME

INTERMITTENT CAUSING THE CONTROL TO MALFUNCTION.

DO NOT MODIFY ANY OF THESE CIRCUITS.

DO NOT CUT OR ADD ANY WIRES IN THIS SYSTEM. TAMPERING WITH THIS

WIRING WITHOUT WRITTEN PRIOR PERMISSION WILL VOID THE WARRANTY.

REQUEST INSTRUCTIONS FROM THE FACTORY SHOULD IT BE DESIRED TO

MODIFY ANY OF THE CIRCUITS.

Î

FIGURE 15

(MSIN0201BE)

Î

All Machines

AIR CONNECTION

MINIMUM 85 PSI (Generally)

MAXIMUM 110 PSI (Check nameplate on machine)

THE BRAKE INTERLOCK PRESSURE SWITCH WILL NOT PERMIT THE

MACHINE TO EXTRACT IF THE AIR PRESSURE IS TOO LOW. THE

MACHINE WILL ROTATE AT DRAIN SPEED INSTEAD.

If this happens, check your air compressor. If your gauge shows more than

85 PSI the gauge is probably faulty. Some air compressors are set with

too great a pressure differential between the lowest pressure obtainable

and the highest pressure obtainable. Hence, if your compressor is set to

go on at 60 PSI and off at 110 PSI, the machine will extract quite

satisfactorily whenever the air pressure is above 85 PSI, but will not enter

extraction at all when the pressure is below 85 PSI.

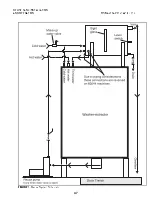

Î

FIGURE 16

(MSIN0201BE)

Î

All Machines

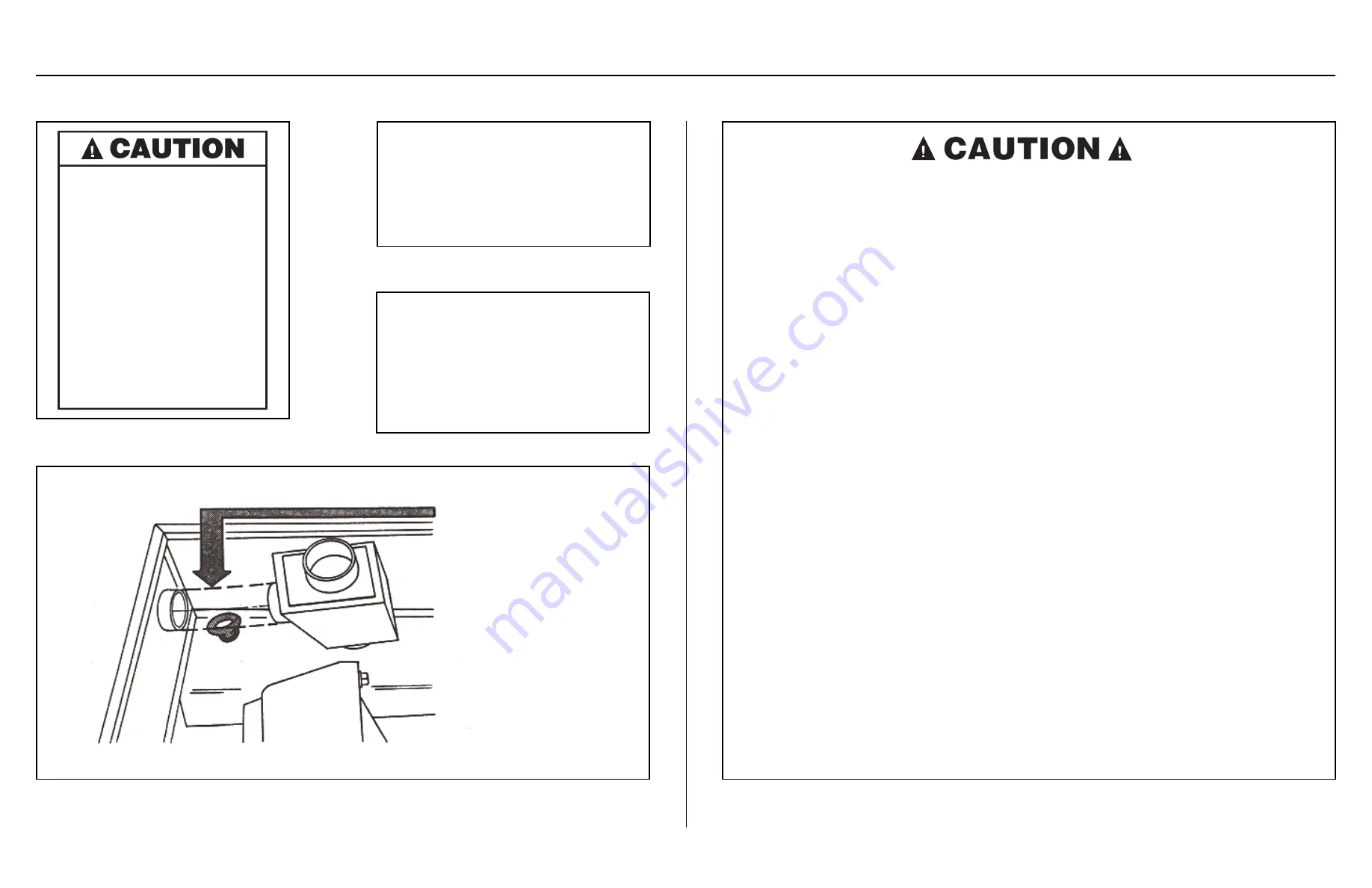

THIS HOSE FROM THE

STAPH AIRTROL

ASSEMBLY TO THE

CLEAN SIDE VENT

SCREEN WAS

REMOVED FOR

SHIPPING PURPOSES

TO PERMIT

ATTACHMENT OF

LOADING SLING TO

SHIPPING EYE BOLT.

REINSTALL AS SHOWN

BEFORE OPERATING

MACHINE.

Î

FIGURE 17

(MSIN0201BE)

Î

Staph-Guard

®

Machines

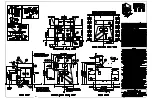

WHEN MAKING ELECTRICAL

POWER CONNECTIONS:

BEFORE SHIPPING, ALL MOTORS ARE PROPERLY PHASED FOR

CORRECT

ROTATION.

IT

IS

POSSIBLE

TO

REVERSE

THE

DIRECTION

OF

ROTATION

IN

A

3

PHASE

MACHINE

BY

INTERCHANGING THE INCOMING POWER LEADS. THEREFORE, THE

ROTATION OF A 3 PHASE MACHINE MUST BE OBSERVED AND

CORRECTED WHEN THE MACHINE IS FIRST INSTALLED. IF IT IS

NECESSARY TO REVERSE THE ROTATION, SIMPLY SWAP THE

INCOMING POWER LINES TO THE MACHINE (NEVER MOVE L3 IF L3

IS A STINGER LEG) - NEVER ATTEMPT TO RECONNECT MOTORS

OR THE MOTOR CONTROL DEVICES.

NOTE:

1. Connections must be made by a competent electrician.

2. Before making power connections, read the instructions

on all related tags.

3. "Stinger leg", if any, must be connected to terminal L3 only.

4. Only use Bussman Fusetron FRN (up to 250V), FRS (up to

600V) or similar lag fuses. The nameplate fuse sizes must

not be applied to standard fuses.

5. See nameplate for fuse and wire size. If wire runs more than

50 feet, increase by one wire size per each additional 50 feet.

Î

FIGURE 18

(MSIN0201BE)

Î

All Hydro-Cushion

®

Machines

43

Summary of Contents for 42044SR2

Page 2: ......

Page 4: ......

Page 8: ......

Page 9: ...Installation 1 5 ...

Page 37: ...Î FIGURE 8 MSIN0301AE Î Vibration Switch Î FIGURE 9 MSIN0301AE Î 60 Staph Guard 33 ...

Page 51: ...586DA4 BUecU CicdU CSXU QdYS B5EC5 D1 9 CD1 1D9 1 4 5B1D9 C9 1 15 1F _V 47 ...

Page 53: ...Dimensional Drawings 2 49 ...

Page 54: ......

Page 55: ...51 ...

Page 56: ...52 ...

Page 57: ...53 ...

Page 58: ...54 ...

Page 59: ...55 ...

Page 60: ...56 ...

Page 61: ...57 ...

Page 62: ...58 ...

Page 63: ...59 ...

Page 64: ......

Page 65: ...61 ...

Page 66: ...62 ...

Page 67: ...63 ...

Page 68: ...64 ...