Ê

Setting Procedures

In order to protect against lateral “creeping” of the machine during operation, due to vibration, it is recom-

mended to roughen the area of the floor where grout will be applied. Anchor bolts are not required; they are how-

ever, recommended on tilting machines. Anchor bolt locations are shown on the dimensional drawing for each

machine. With the machine near the final destination, unbolt the shipping skids. Observing all precautions, lift the

machine off its skids and lower the machine onto blocks as follows.

Ë

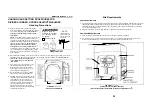

For 42", 48" and 64" Open Pocket Machines

1. Place blocks in each of the four corners of the foundation. The blocks should be high enough to hold the base

plate approximately 1" above top of slab (See FIGURE 3).

2. Lower the machine onto blocks and shim the machine as required until it is level. When leveling the machine,

place the level on the top edge of the frame, not on the belt guard.

3. When the machine is level and has room

for at least 1" of grout under each base

plate, apply the grout under the full

length of each base plate. Take care to

fill all voids with grout to assure that

there is a solid base of grout under each

base plate (for additional information,

see “Grouting and Anchoring Considera-

tions” in this section).

4. When the grout has hardened, tighten

down the anchor bolts (if used) evenly

using only one quarter turn on each bolt

before moving to the next one. While

tightening, frequently skip from front to

back and right to left to insure uniform

tension. After tightening all bolts, check

each bolt at least twice during the first

week of operation. At this point, service

connections (air and electric power)

should be made to the machine. See

“HYDRO-CUSHION

®

SERVICE CON-

NECTIONS...” for procedures.

5. With air and power connected, set the Master Switch to FORMULA or to ON (as appropriate) to activate the

push-downs, then remove hold down bolts and plates (marked with red) which hold the shell to the frame.

De-energize machine.

6. On 42" and 48" tilting machines only, remove the four hold down bolts (marked with red) that hold the lower

side frame channels to the base pad. On 64" tilt forward only machines (BTL models), remove the rear tilt

wheel clamps only. On 64" tilt both way machines (BTN models), remove all four tilt wheel clamps.

Clamps to be removed will be marked with red.

Î

FIGURE 3

(MSIN0203AE)

Î

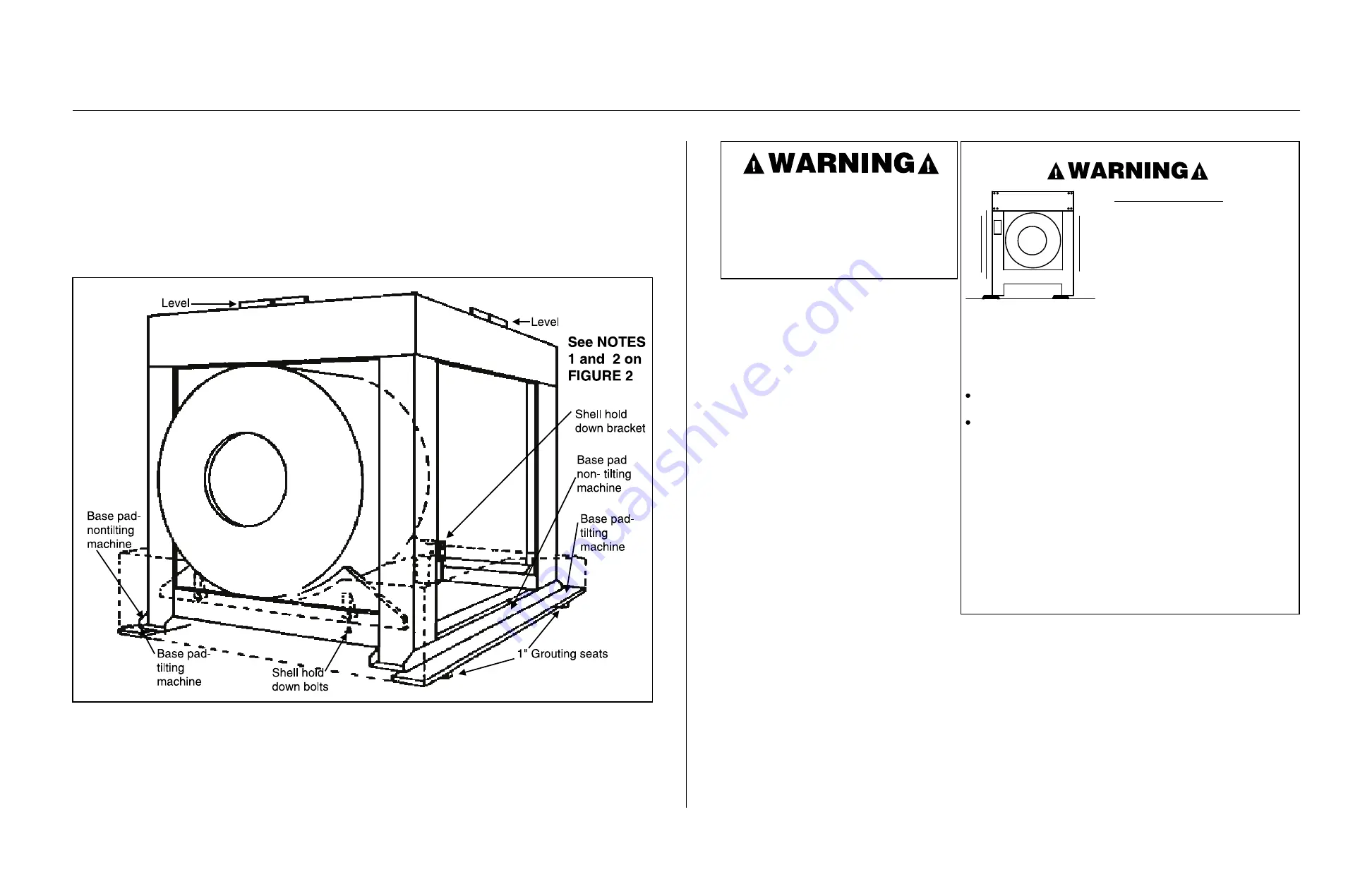

Setting 42", 48", or 64" Open Pocket Machines

REMOVE SHIPPING RESTRAINTS BEFORE

ATTEMPTING TO RUN MACHINE but only

after machine is in place. Restraints are usually

marked with red, and may be concealed behind

access panels.

REPLACE THOSE FEATURES WHICH ARE

PART OF MACHINE STRUCTURE.

Î

FIGURE 4

(MSIN0203AE)

Î

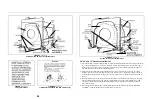

Shipping Restraints

A SUSPENSION TYPE MACHINE

CAN "WALK" OUT OF POSITION

DURING EXTRACT, ENDANGER-

ING PERSONNEL AND DAMAG-

ING EQUIPMENT, IF NOT

PROPERLY INSTALLED.

Roughen floor, install anchor bolts and

grout under all base pads to prevent

"teeter-totter" and sideways movement.

REMOVE ALL SHIPPING RESTRAINTS but only after

machine is in place.

THE MACHINE WILL MALFUNCTION AND MAY BE DAMAGED

UNLESS ALL SHIPPING RESTRAINTS (USUALLY MARKED

WITH RED) ARE REMOVED. Restraints may be located behind

access covers. These include but are not limited to:

Cylinder hold-down bolts, brackets, straps and/or blocking

(suspension type machines).

Vibration safety switch restraint (all 36" and larger machines).

REPLACE FASTENERS WHICH ARE PART OF MACHINE

STRUCTURE.

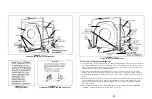

TO REMOVE BRAKE BAND SHIPPING BLOCK

once machine is connected to electricity and air.

1. Energize machine.

2. Turn brake on using manual operating procedures (see

manual).

3. Insure that no one can inadvertently operate the machine

controls; then using tools, not bare hands, remove block while

brake is released.

4. Manually turn brake off.

Î

FIGURE 5

(MSIN0203AE)

Î

Anchor and Grout Warning

24

Summary of Contents for 42044SR2

Page 2: ......

Page 4: ......

Page 8: ......

Page 9: ...Installation 1 5 ...

Page 37: ...Î FIGURE 8 MSIN0301AE Î Vibration Switch Î FIGURE 9 MSIN0301AE Î 60 Staph Guard 33 ...

Page 51: ...586DA4 BUecU CicdU CSXU QdYS B5EC5 D1 9 CD1 1D9 1 4 5B1D9 C9 1 15 1F _V 47 ...

Page 53: ...Dimensional Drawings 2 49 ...

Page 54: ......

Page 55: ...51 ...

Page 56: ...52 ...

Page 57: ...53 ...

Page 58: ...54 ...

Page 59: ...55 ...

Page 60: ...56 ...

Page 61: ...57 ...

Page 62: ...58 ...

Page 63: ...59 ...

Page 64: ......

Page 65: ...61 ...

Page 66: ...62 ...

Page 67: ...63 ...

Page 68: ...64 ...