Ë

Foundation Requirements

—The floor and/or all other support components must have sufficient strength

(and rigidity with due consideration for the natural or resonant frequency thereof) to withstand the fully loaded

weight of the machine, including the wet goods and any repeated sinusoidal (rotating) forces generated during its

operation. Determining the suitability of floors, foundations, and other supporting structures normally requires

analysis by a qualified structural engineer.

Ë

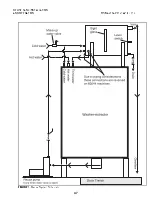

Drain Requirements

—An open trench must be provided

in the floor for draining. Its size (as a minimum) and location

(centered under the drain valve) should be as shown on the

dimensional drawing and with a minimum slope of 1/8" per foot

to the sewer. Even where one trench serves several machines,

the cross section area of the trench shown on the dimensional

drawing is normally acceptable since draining is intermittant

and the portion of the trench located under each machine is suf-

ficient to contain most, if not all, of the outfall from one machine.

Refer to local codes for sanitary requirements such as traps, etc.

Ê

Setting Procedures

To protect against lateral “creeping” of the machine during operation, due to vibration, roughen the area of the

floor where grout will be applied. Anchor bolts are not required with these machines but may be used if desired.

Once the foundation is prepared, the shipping skids are removed and the machine is ready to be set in its desired

position. See FIGURES 3 and 7, then proceed as follows:

1. Lower the machine onto three short lengths of 2 x 4’s such that the shell front is resting on two of them and

the third is centered under the shell back.

2. Put shims on top of the 2 x 4’s until

the machine has approximately 1"

clearance under each base pad and

is level. Check level as shown in

FIGURE 3.

3. When the machine is level and has

room for 1" of grout under each

base pad, apply the grout. Fill all

holes under the base pads so that

each pad is resting upon a solid

base of grout.

4. When the grout has hardened, tighten

down the anchor bolts (if used) and

remove the four hold down bolts.

The shell will be lifted by the

Hydro-cushion

®

cylinders so that

the 2 x 4 blocking may be removed.

REMOVE SHIPPING RESTRAINTS BEFORE

ATTEMPTING TO RUN MACHINE but only

after machine is in place. Restraints are usually

marked with red, and may be concealed behind

access panels.

REPLACE THOSE FEATURES WHICH ARE

PART OF MACHINE STRUCTURE.

Î

FIGURE 4

(MSIN0301AE)

Î

Shipping Restraints

WITH SKIDS REMOVED THERE IS MINIMAL

CLEARANCE BETWEEN BRAKE SHOE ARMS

AND GROUND.

BE CAREFUL NOT TO DAMAGE THESE PARTS WHEN

MOVING THIS EQUIPMENT. MANUFACTURER NOT

RESPONSIBLE FOR CONCEALED DAMAGE. INSPECT

BRAKE ARMS TO PROTECT YOUR INTEREST.

Î

FIGURE 5

(MSIN0301AE)

Î

60" and 72" Staph-Guard

®

Î

FIGURE 6

(MSIN0301AE)

Î

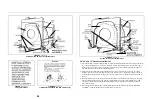

Drip Shields

Î

FIGURE 7

(MSIN0301AE)

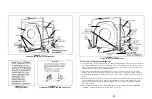

Î

Anchor and Grout Warning

32

Summary of Contents for 42044SR2

Page 2: ......

Page 4: ......

Page 8: ......

Page 9: ...Installation 1 5 ...

Page 37: ...Î FIGURE 8 MSIN0301AE Î Vibration Switch Î FIGURE 9 MSIN0301AE Î 60 Staph Guard 33 ...

Page 51: ...586DA4 BUecU CicdU CSXU QdYS B5EC5 D1 9 CD1 1D9 1 4 5B1D9 C9 1 15 1F _V 47 ...

Page 53: ...Dimensional Drawings 2 49 ...

Page 54: ......

Page 55: ...51 ...

Page 56: ...52 ...

Page 57: ...53 ...

Page 58: ...54 ...

Page 59: ...55 ...

Page 60: ...56 ...

Page 61: ...57 ...

Page 62: ...58 ...

Page 63: ...59 ...

Page 64: ......

Page 65: ...61 ...

Page 66: ...62 ...

Page 67: ...63 ...

Page 68: ...64 ...